A ball valve is a type of shut-off valve that stops, starts, and changes the flow of gases, liquids, and vapors in a pipe system by turning a ball inside the valve. The ball is affixed to two seats and is linked to the operating and control mechanism that causes its rotation via a shaft. The cross-section of the bore is perpendicular to the flow area, and the valve restricts the passage of the fluid. The rate at which the fluid flows through the valve is proportional to the area interacting with the floor.

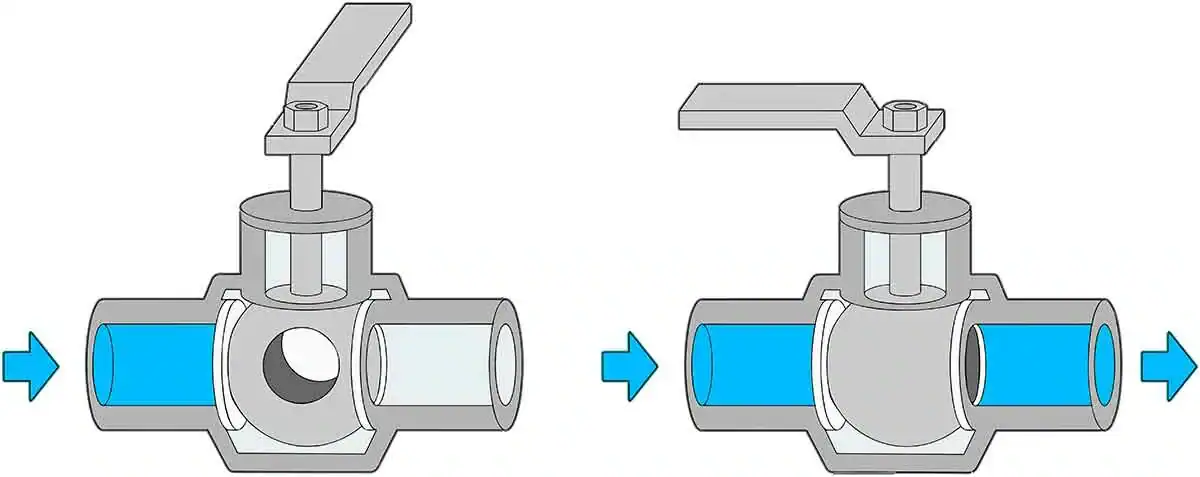

The fundamental way of functioning of a ball valve requires an operator’s manual turn of a lever or a wrench. To open or close the valve, torque is utilized to rotate the lever arm 90° in either a clockwise or counterclockwise direction. A parallel lever arm to the pipes indicates an open valve. Ball valves are available in various styles and configurations to meet the diverse requirements of industries. The specifications and standards for ball valves differ by industry in which they are used.

1. General Applications For Ball Valve

Ball valves are often used to shut off fluid flow in domestic and offshore oil and gas production facilities. They are also used to feed burners with fuel gas. It is the function of ball valves to control the flow of high-pressure liquids and gases with little pressure drop. These valves can quickly open and close because they have a very low response time. They can also seal tightly with minor force.

For example, ball valves can be used as shut-off valves for homes, businesses, and other places in air conditioners. The design, the closing material, and the welds should all work together to make a safe structure that meets the most challenging needs, like high working pressure when using refrigerants like R410A.

Inside the garden, ball valves may be used for different types of watering. Ball valves can be attached to outdoor hoses, taps, sprinkler lines, or watering cans. Turn off the main water supply when attaching the ball valve to the main water line. Add water to the mains through one of the ball valve’s ports.

2. Fabricating Types of Ball Valves

Each ball valve intended for a particular application, such as gas ball valves, will also be labeled accordingly. Regardless of the specific ball valve variety under consideration, the majority will comprise four primary components. The components include the valve housing, the central metal ball, the seating mechanism that secures the ball within the valve, and the lever used to turn the ball valve from the on/open to the off/shut state. Typically, stainless steel, brass or nickel-plated brass, P.V.C., or a comparable robust plastic polymer compose the body of a ball valve. Typically, the spheres are crafted from brass or stainless steel, with nickel-plated or chrome-plated brass being the most common materials. Another way distinct ball valve models and configurations are differentiated is by the numerous attachment or fitting types. Manual ball valves with compression fittings or threaded fittings may be among these. Complex designs of ball valves may provide additional flow control options beyond the standard on/off function. Both flanged and vented ball valves are available; the position of the lever can determine which one produces which flow outcome. Your application, the nature of the fluid to be regulated, the required flow rate, and the pressure rating of your system will impact which variety of ball valves is most suitable.

1) Full Port Ball Valves

In a full bore, the diameter of the bore is similar to that of the pipe. In full-bore valves, the flow area of the fluid remains constant, resulting in an exceptionally low flow resistance. Due to the minimal frictional loss encountered during fluid flow, the pressure decrease is also minimal. An increased pressure decrease in a piping system complicates the process of pumping. However, due to the need for the bore diameter to correspond to the pipe size, a more extensive housing and ball are necessary, resulting in a higher cost than a reduced bore.

2) V-Port Ball Valves

A V-port ball valve is a type of control valve that consists of a V-shaped ball or seal. The ‘V’ design facilitates fluid regulation. The molded v-bore differentiates v-port ball valves from other varieties of ball valves.

V-port ball control valves are generally preferred for fluid regulation due to their ability to produce linear flow characteristics. The flow properties of a v-port ball valve differ from those of standard port ball valves. As the shaft rotation of a v-port ball valve increases, fluid flow has a corresponding linear increase.

3) Cavity Filler Ball Valves

The seat design of a cavity-filled ball valve links the distance between the ball and its body. This prevents the accumulation of particles or entrapped media around the ball over time, both of which have the potential to obstruct the fluid flow or cause contamination. Ball valves with cavity-filled balls are simpler to clean and sanitize. Cavity-filled ball valves are invaluable in sanitation-critical industries such as the food, drug, and bioprocessing industries.

4) Multiport Ball Valves

Multiple fluid streams are diverted, combined, divided, or turned off via multi-port ball valves using a ball with an L-shaped or T-shaped bore segmented through its center. A multi-port valve can divide a flow upstream to the inlet into multiple discharge streams. Although it can divide a flow, it cannot allocate it to its outflow streams at predetermined flow rates. Additionally, it can join several flow streams into a single stream or change the flow direction of the fluid.

5) Trunnion Ball Valves

In a trunnion ball valve, the ball is supported by a trunnion, an extra tube at the bottom. This stops the ball from moving and keeps it in place along its axis. The valve shaft has to turn for the ball to move. The pressure of the fluid moves the springs toward the ball held by the trunnion. This makes a tight seal. They are also excellent for high-pressure situations because the fluid pressure is spread to the trunnion and the seat springs.

6) Floating Ball Valves

Ball valves with cavity-filled balls are simpler to clean and sanitize. Cavity-filled ball valves are invaluable in sanitation-critical industries such as the food, drug, and bioprocessing industries.

3. What Is the Difference Between One-Piece, Two-Piece, and Three-Piece Ball Valves?

1-piece, 2-piece, and 3-piece ball valves, while all falling under the umbrella of ball valves, have distinct characteristics that make each suitable for particular applications.

1) One-Piece Ball Valve

An internal component housing a one-piece ball valve is a single-piece cast body of the ball valve. This effectively diminishes the potential for fluid leakage from the valve. One-piece ball valves are the most suitable ball valve type with a reduced bore. The welded one-piece ball valve is more prevalent but cannot be disassembled for cleansing or repair after damage. Consequently, it is restricted to applications where sanitation is not a significant concern and particulate accumulation is unlikely. In contrast, the disassembly of screwed one-piece ball valves necessitates specialized equipment, while servicing, repair, and cleaning are all possible.

2) Two-Piece Ball Valve

A two-piece ball valve comprises a housing divided into two interlocking parts. The ball is contained in the main piece, which is also connected to one end, while the internal components are held together in the secondary piece, which is also connected to the other. Housings consisting of two pieces are the most prevalent on ball valves. The two components are detachable for cleansing, maintenance, and inspection; however, this process necessitates the extraction of the valve from the conduit.

3) Three-Piece Ball Valve

A three-piece ball valve housing contains internal components that are secured and fastened to its two extremities via fastener connections. Welded or threaded connections are attached to the primary pipe. Three-piece ball valves are utilized in applications that are highly dependent on valves and require frequent maintenance. Three-piece ball valves are frequently employed in industries where sanitation is critical to product quality and safety, such as the food and beverage and pharmaceutical sectors.

Depending on the particular demands of the application, each form of ball valve may be produced from an extensive array of materials, such as bronze, brass, stainless steel, and others.

4. What Are the Components of a Ball Valve?

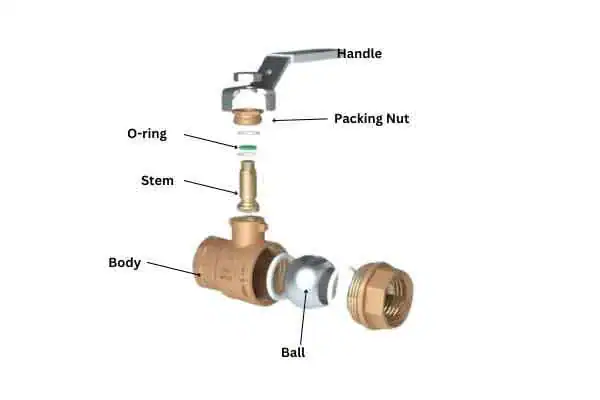

The primary spare parts for ball valves are as follows:

1) Body

The body or valve enclosure contains all internal components of a ball valve. The ball valve’s components are safeguarded by a thermoplastic or thermoplastic-lined metal structure composed of a hard and rigid material. It also gives access to the external control mechanism responsible for the ball’s rotation.

2) Rotatory Ball

The primary distinguishing feature that sets ball valves apart from other valves is the presence of a center opening or aperture in the ball. By this central hole, the media is directed. Through one axis, this aperture connects the inlet to the outflow.

3) Stem

The stem is the interface between the rotary ball and an external control system in a ball valve. For instance, the stem is linked to a handle or actuator in a manually operated ball valve.

4) Bonnet

The bonnet conceals the orifice in the ball valve visible through the body’s opening. Additionally, it functions as a pressure boundary. The packaging encircles the stem and acts as an impenetrable barrier to the substance.

5) Seats

Discs are utilized as supports between the body and the projectile. They provide support and a barrier between the object and the body. The seats of the ball valves uniformly distribute the seating tension and function as a seal to enclose the fluid.

6) Handle or Actuator

It must be supplied with energy through a manual or actuated power source. Automatically actuated energy is powered by an electric, hydraulic, or pneumatic source. In contrast, manually operated actuators require the manipulation of handles and levers.

7) Rotatory Ball

The primary distinguishing feature that sets ball valves apart from other valves is the presence of a center opening or aperture in the ball. By this central hole, the media is directed. Through one axis, this aperture connects the inlet to the outflow.

8) Gaskets

Gaskets are vital sealing components that prevent leaks between various valve body parts. They significantly contribute to the waterproof characteristic of ball valves. The packaging encircles the stem and acts as an impenetrable barrier to the substance.

5. What Are the Different Types of Ball Valve Connections?

To properly connect to process lines or other parts, ball valves need different end connections depending on their use and where they are installed. Different connection types accomplish the same thing: connecting both sides of the ball valve to the pipe or part. However, some connection types work better in certain situations. These are some popular ways to connect a ball valve:

1) Threaded connections:

Threaded connection ends make it simple to attach tiny valves to pipelines. The valve usually has female threaded ends that join to a male threaded part. The valve may have two male-threaded ends or one male-threaded end and one female. To make the threads, strict adherence to thread standards is required. These standards describe the thread’s properties.

2) Tri-Clamp Connection:

It’s also called a Tri-Clover or a T-Clamp. A Tri-Clamp is a flanged link where a flexible clamp with a seal in the middle holds together the flanged ends of the pipe and valve. Tightening the clamp squeezes the pipe and the valve end together, ensuring the link is sealed. Clamps come in several styles, including single hinge, three-segment double hinge, and two-bolt high-pressure.

3) Socket Weld Connections:

This kind of welded connection has a valve that is wider than the pipe so that the pipe can fit into the valve socket end. The weld is done around the edge of the end of the valve that fits on the pipe.

4) Flanged Connections:

For valves larger than 4, flanged connections are preferred. They are simple to implement and can be taken out for upkeep and cleaning without affecting other pipe network parts. Metal pieces with holes in them are called flanges. Bolts and nuts are used to attach the valve to the pipe. These parameters describe factors like how the plates should be made, the size and thread of the holes, and where the holes should be located.

5) Butt-welded Connections:

The connection is welded, so the valve and pipe ends are the same size. The ends of the link are pressed against each other and cut to make room for the weld. Welding is done around the edges of the joint. Smaller pipe sizes often use butt welding.

6) True Union Connection:

Most P.V.C. valves and pipes use true union connections, where the pipe’s outside diameter fits the connection’s inside diameter. To stop leaks, a chemical (glue) is used. They make it possible to connect and separate the ball valves from the pipe more than once, which is useful for repair or replacement. Often, P.V.C. parts are used in acidic liquids like seawater, acids and bases, and organic solvents.

6. Ball Valves Types Manufacturing

Ball valve types of applications. Understanding their differences is key in selecting the right Ball valve for a given task.

A ball valve is a type of shut-off valve that turns a ball inside the valve to start, stop, and control the flow of gases, liquids, and vapors in a pipe system. Three parts connect the ball to the machine that moves and controls it: two seats, a shaft, and the machine itself. Flow can’t go through the valve if the opening’s cross-section isn’t straight across from the flow area. The valve lets water flow; how much of the hole can be seen from the floor depends on how open it is.

The way the ball valve works is similar to how the butterfly valve works. It is made up of a sphere with a hole drilled through the middle of it. The flow is either open or closed based on where the circular opening is placed. The ball is linked to the stem, which is linked to the handle or activator of the tool.

To start the fluid flow, the pump turns about 90 degrees clockwise. It turns the stem, which makes the ball turn. When the ball’s opening lines up with the fluid path, the valve lets fluid move through. The actuator turns 90 degrees counterclockwise, the stem turns the same way as the ball turns 90 degrees counterclockwise, and the flow of fluid stops.

To control the flow, the ball can be kept in both partially open and partially closed positions. When there is a high-pressure drop and the valve is left partly open for a long time, the flexible seats flow around the ball’s opening edge. They might be able to stop the ball in its path.

7. Ball Valve Specifications

As a ball valve manufacturer-Plumberstar, we can provide and identify more different ball valves and gate valves here.

1) Ball valves for home appliances

Many home plumbing systems use ball valves to prevent main water or branch blockages from happening when leaks occur. They are also used in model home appliances like water faucets, heaters, bathrooms, and washing machines.

2) Ball valves for refrigerators

Ball valves are residential air conditioners, industrial HVAC, and refrigerator shut-off valves. When handling refrigerants like R410A, the closing material, construction, and welds have to be capable of ensuring the production is safe under the toughest conditions, i.e., high working pressure.

3) In the oil and gas business

Ball valves are often used as liquid shutdown valves in gas and oil production facilities on land and at sea. They are also used to keep gas heaters running smoothly. It is suggested that ball valves control the flow of fluids and gases with high pressure while causing the least pressure drop. They have the right amount of low reaction time, which means they open or close quickly, and these regulators can fit tightly with little force.

8. Ball Valve And Gate Valve

As a gate valve manufacturer, Plumberstar, we can provide and identify more ball valve and gate valve differences here, which are from applications, maintenance, Midea, port, etc.

1) Ball Valve Maintenance

The most effective way of ensuring it works well for an extended period is through regular repair. In the first year of use, check the valve for signs of a leak. Quarterly, open and close the valve by turning the handle four times.

2) Gate Valves Maintenance

As you install gate valves, check to see if there is any damage there. Clean the valves at least once a month when you’re not using them. This will keep the outside and inside from getting grimy with dust and dirt.

3) Media and the Port

Gate valves and ball valves are both commonly used in fluid handling systems, but they offer different advantages depending on the application. Gate valves feature a full-port design when fully open, allowing unimpeded, straight-through flow. This makes them ideal for handling thick media, slurries, or applications where minimal flow resistance is critical.

Ball valves, on the other hand, come in full-port, reduced-port, and V-port configurations. Full-port ball valves function similarly to gate valves in the open position, offering low resistance to flow. However, V-port ball valves provide more precise flow control, enhancing their versatility in systems where modulation is required.

While both valve types offer excellent performance, the right choice depends on your specific operational needs. Consulting with an experienced valve manufacturer or industry professional is recommended to ensure the best fit for your application.

9. Stainless Steel Vs. Brass Ball Valves

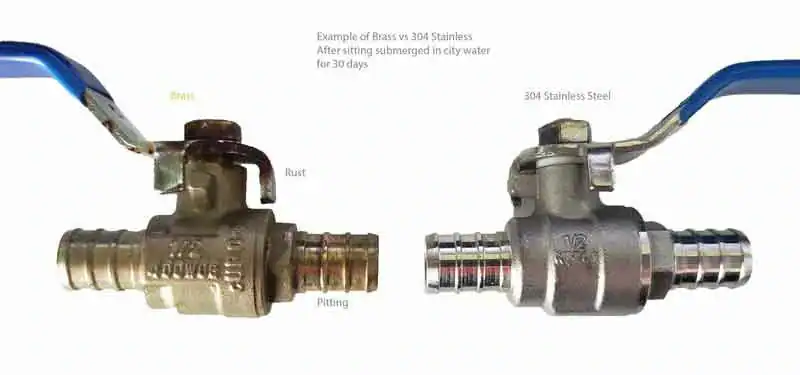

When choosing a ball valve for a particular application, the material of the valve plays an important role. What follows is a contrast between stainless steel and brass ball valves on some key aspects:

Iron alloyed with chromium and nickel produces high-resistance stainless steel. Because stainless steel ball valves are known to be resistant to leakage, able to withstand a broad spectrum of temperatures, and perform nicely under pressure, this material would be ideal for control and shut-off service.

The stainless steel ball valves are a durable option even under environments with extremely high rates of corrosion; 316 stainless steel is an especially corrosion-resistant variety that contains molybdenum—a silvery metal with an extremely high melting point—along with nickel, in addition to ordinary stainless steel.

Brass, being an alloy of copper, zinc, and at times other metals, can also be utilized for the manufacture of ball valves. Brass ball valves may contain small amounts of lead, typically below 2%. The FDA limits the application of certified lead-free brass ball valves in light of the potential health threat posed by lead.

Flexible sealing is the initial component to fail in a metal ball valve. This means a brass ball valve will last as long as a stainless steel ball valve before finally failing in most applications. Where the use of an inherently corrosion-resistant metal is not a requirement, brass will provide the same durability as stainless steel. Some applications, including residential and commercial properties, water wells, and HVAC, make extensive use of brass ball valves. F.D.A. requirements insist that lead-free brass ball valves approved by the regulating authority should be used in some applications, for example, in food processing or drinking water.

1) Cost Effectiveness

Among the cost advantages that set brass ball valves apart from stainless steel is cost-effectiveness. Due to its comparatively lower cost when compared with stainless steel, brass is utilized lavishly in plumbing systems. Aside from this, it is much simpler to produce brass ball valves compared with valves made of stainless steel, meaning reduced expenditure, and ultimately, they are cheaper. Also, since brass valves are not required to be polished, this reduces expenses. Brass ball valves are optimal for those who wish to save money without sacrificing quality or durability due to this benefit.

2) Corrosion Resistance

Due to its superior corrosion resistance, brass ball valves are ideal to be used in aggressive environments. Brass has a resistance against corrosion and corrosive and basic substances, and does not more as stainless steel. The heat resistance extends the life of brass ball valves, and no maintenance or replacement is required periodically. Ultimately, this benefit is rewarded in terms of more value for money spent.

3) Heat Resistance

Additionally, brass ball valves have better heat resistance than stainless steel. Brass is not distorted, bent, or broken by high temperatures. They can both be performance-oriented and long-lasting, and that is the reason they are a great material to utilize whenever thermal resistance is necessary, for example, in hot water circulation systems.

4) Versatility

Additionally, brass ball valves are multi-purpose and can be utilized in various industries and applications. Along with a host of other applications, they are also utilized in plumbing, HVAC, industrial equipment, and fire protection systems. Their long-lasting quality and dependability make them the preferred option among many industry professionals.

5) Ease of Installation

The second benefit of brass ball valves is that their installation is straightforward. Most brass ball valves are two-way and threaded to allow them to be mounted into the plumbing system. Further, the material possesses superior flexibility, and it is convenient for plumbers to cut, distort, or reshape it to meet demanding installation specifications.

10. Applications For Stainless Steel Ball Valves:

Due to their resistance to corrosion, high temperatures, and high pressures, stainless steel ball valves find widespread application in construction, manufacturing, and industrial processes. The following are some of the most prevalent uses for stainless steel ball valves:

- Petroleum refining

- Marine operations

- Brewing systems

Brass ball valves are on par with stainless steel ball valves in most uses in terms of durability and efficiency. In those applications where very high temperature or pressure is required, stainless steel or other higher-strength materials may be more suitable. Even so, the flexible seals, usually constructed from PTFE, will be the weakest component. This calls for the use of special barrier materials in such extreme uses

11. Factors to Consider While Buying The Ball Valve

When purchasing a ball valve, there are several factors and concerns that you need to keep in mind to ensure that you’re getting the right product for your needs. Here are some critical considerations

1) Temperature Range

Identify the pressure and temperature range that the application withstands. Ensure the temperature tolerance of the valve is compatible with the operating temperature of your system.

2) End Connections

Compatibility with the conduit system and suitability for installation, considering the end connection type. Threaded, socket weld and butt weld connections are all prevalent alternatives.

3) Raw Materials

In choosing a valve material, make sure that it is compatible with the fluid being processed and with the environment around it. Brass, stainless steel, carbon steel, PVC, and bronze are common materials. Temperature limitations, corrosion resistance, and chemical compatibility are considerations.

4) Flow Characteristics

Consider the flow features of the application. A complete port ball valve may be more suitable if you want to reduce pressure loss in applications requiring high flow rates. Cost-effective reduced-port ball valves may be utilized when the flow rate is not of the essence.

12. General Fluid Management Solutions of Ball Valve

Discover our general fluid management solutions featuring ball valves, designed to excel in water control and adaptability across various applications. As a reliable ball valve supplier, we cater to the diverse needs of our clients, including bulk order requirements. Our commitment to innovation and quality ensures the delivery of top-notch performance ball valves, with unparalleled efficiency in fluid control for a wide range of industries. Trust our expertise to enhance your water control systems and support your business growth.

1) Brass Gas Ball Valve

- 1/2×1/2 inch,3/8“,3/4″,90degree open

- CW617N, DR Low-lead brass

- Brass Ball

- Aluminum handle&Zinc alloy, Steel handle with painting

Enhance your gas control systems with our precision-engineered brass gas ball valves, offering exceptional performance and safety.

2) Butterfly Water Ball Valve

- Butterfly Ball valve with 1/2″-1″

- 2PC with PN40

- Brass body with nickel-plated and Aluminum alloy handle

- NPT&BSP thread connection with nice shape

Our valves ensure reliable and proficient water flow control for many applications. Rely on our skillfully designed Butterfly Water Ball Valves for all your water management requirements.

3) Brass Electrical Ball Valve

- 1/2-1 inch with G(BSP)threaded

- 230V and 24V-AC

- Brass body and motor with a 2-year guarantee

- 100% water leakage and operation test

Explore our Brass Electrical Ball Valves, meticulously designed for efficient fluid control in applications such as HVAC systems, water treatment plants, and industrial processes.

13. Difference Between Ball Valves and Globe Valves

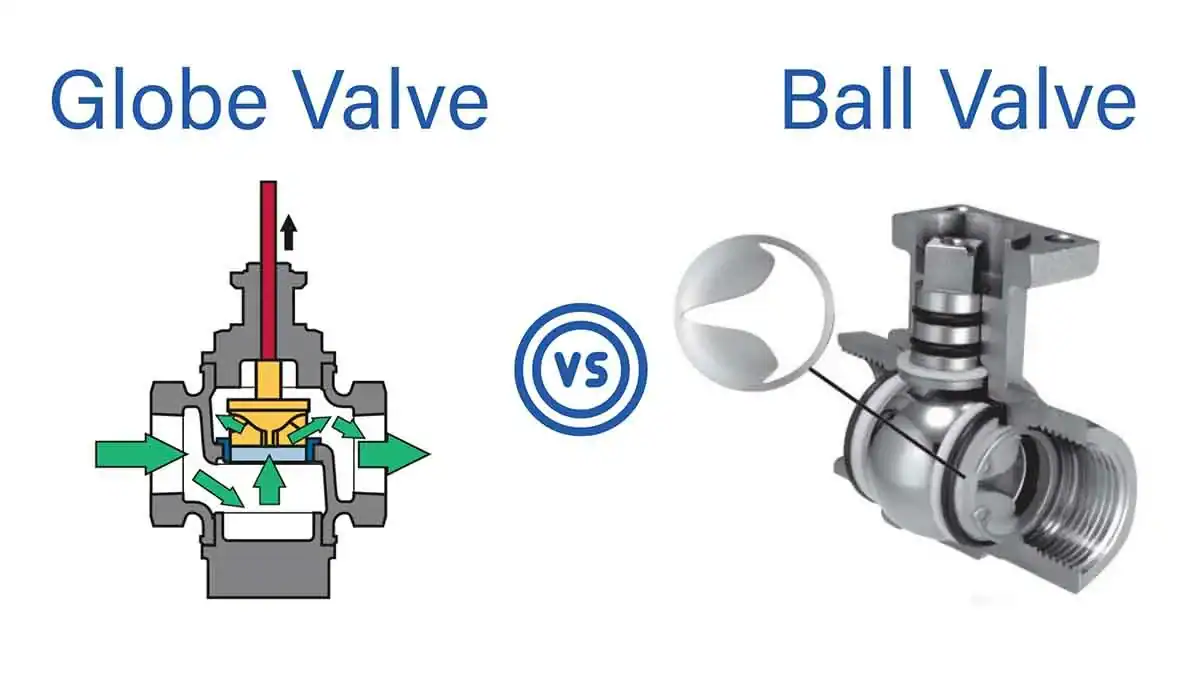

Globe Valves and Ball Valves are two prevalent types of valves that find application in a wide range of situations. Every individual possesses distinct qualities and is more suitable for particular tasks. A comparison between the two is as follows:

1) Valve Design

Below are two different designs:

(1) Globe valve design

There are three fundamental configurations of globe valves: T- or Z-globe valve, Y-globe valve, and angle globe valve. Consult our article on globe valves for detailed descriptions of each variety.

(2) Ball valve design

Various classifications of ball valves are possible based on the housing structure, ball design, and port size. Depending on the structure of the enclosure, ball valves may consist of one, two, or three pieces. Ball valves are classified as reduced port ball valves, standard port ball valves, or complete port ball valves, according to the extent of the port. Further, the number of ports determines the classification of ball valves into two-way or multi-port valves.

2) Flow Control

Both globe and ball valves function to regulate the passage of fluid. However, they can also operate in a partially closed or open state to regulate the flow rate. This flow regulation is possible because the disc of the globe valve is positioned in parallel with the flow. Globe valves attain a greater linear flow rate than ball valves, thereby minimizing the impacts of water pressure.

3) Applications

Globe valves are utilized for fluid flow regulation. In addition, globe valves offer distinct benefits in scenarios that necessitate accurate throttle regulation. In contrast, ball valves are frequently employed to isolate and turn off plumbing systems. Fuel oil and cooling water systems are industrial applications for globe valves, whereas the chemical storage and natural gas industries utilize ball valves.

14. What Are the Best Ways to Assess the Quality of Ball Valve?

For your ball valve to endure and function appropriately, you must select a high-quality one. For a ball valve to be of high quality, you should do the following:

1) Inspection by Sight

First things first, have a look at the ball valve. Check the outside of the valve for obvious flaws or irregularities. Verify that there are no obvious signs of damage or distortion on the body, ball, stem, and seats.

2) Evaluating Dimensions

Check the valve’s diameter, length, and thickness to ensure it meets all the specifications.

3) Analyzing the Materials

Verify that the material listed for the valve is accurate. Techniques such as spectroscopic analysis may be used to analyze materials.

4) Pressure Testing

Pressure testing is very important. To determine that the valve will be capable of withstanding pressure with no leakage, it is closed normally and pressurized on one side. Then release pressure slowly while searching for stem or seat leaks. Suitable procedures for such a test are API 598 and ISO 5208.

5) Functionality Test

It is also crucial to carry out a functionality test. To ensure everything works smoothly, open and shut the valve many times. Before operating the valve at its maximum working pressure, be sure it can be turned effectively.

6) Non-Destructive Testing

Dye penetrant inspection (D.P.I.), magnetic particle inspection (M.P.I.), ultrasonic testing (U.T.), and radiographic testing (R.T.) are a few of the non-destructive testing (NDT) techniques that may be applied to reveal interior defects, as per the application.

7) Documentation

As a general rule, testing should only be carried out by qualified individuals by established methods and standards. Since various valves may need distinct testing protocols, you must always consult the ball valve manufacturer’s guidelines.

15. Key Factors When Choosing a Ball Valve Supplier

Ball valves play an integral role in managing the flow of fluids in various industrial and residential applications. It’s crucial to find a reliable ball valve supplier to ensure consistent quality and safety.

Choosing an experienced supplier is crucial. Ball valve suppliers who have been around for a while have shown they can handle industry ups and downs and always provide what their customers need.

1) Treatment of Material

How raw materials, such as brass, stainless steel, or any other metal, are handled may have an impact on their performance, in addition to the sourcing process. Processes like alloying or even unique treatments may be used to increase the lifetime and durability of materials.

2) Standards and Product Quality

We will not compromise on quality. Ensure the ball valve supplier’s products are certified and up to industry requirements. Quality assurance procedures and material selection influence valve performance

3) Technical Support and Customization

Solutions tailored to your specific operating demands may be necessary. To ensure the valves fit your needs, look for a source offering technical assistance and customization options.

4) Exploring Potential Wholesalers

Look online first and inspect the supplier’s website, read reviews, and check ratings. You may learn a lot about a supplier’s strengths and shortcomings from customer interactions. Communicate and inquire with prospective vendors face-to-face. Get to know their offerings, services, and personalization choices. Customer happiness is their priority, so they communicate quickly and clearly.

5) Learning About Price Structures

Evaluate price quotations from various vendors. Prices that look too low should raise red flags. Get a feel for the price system, and make sure you ask about any hidden fees.

6) Assessing Supplementary Service Options

Think about adding value with services like maintenance, technical support, and post-purchase help. These services improve things in the long run and improve the whole thing.

7) Fame on a Global Scale

It’s not enough to have qualifications; these certifications must be recognized globally. Marks such as ISO, ANSI, or CE are trusted by people worldwide and are easily recognizable. Certifications emphasizing safety standards are particularly important for valves intended for critical applications. Inspect their commitment to safety by looking at their safety milestones, any violations, and the steps they take to fix them.

Understand what the ball valve supplier’s testing protocols are. We guarantee the valves’ dependability under diverse situations by thoroughly testing them, including pressure and leakage tests. To keep projects on schedule, logistics and timely delivery are of the utmost importance. For on-time order delivery, inquire about the supplier’s shipping and delivery procedures.

8) Research and development priorities

Technologically, if a provider spent a lot of money on R&D, they want to be the first to market with new technologies.

16. The Common Pitfalls While Purchasing Ball Valve

To mitigate these risks, emphasize Ball valve quality control, ensuring that your supplier is dedicated to maintaining consistent and reliable products. Additionally, prioritize Ball valve standards compliance to guarantee that your valves adhere to the industry’s necessary safety and performance requirements.

- Steel ball instead of the original brass

- Zinc alloy body instead of brass body

- Reducing the port instead of a full port

- 400WOG instead of 600WOG

- 1% water pressure leakage test says 100%

17. The Materials for Manufacturing of Ball Valve

Below are the commonly used materials for ball valves:

1) Brass

Brass is priced higher. Because brass is more resistant to heat than plastic, brass ball valves are an excellent option for residential plumbing applications. Brass is considerably more malleable than stainless steel and can be easily welded. Lead is occasionally added to brass (usually in concentrations below 2%); therefore, opt for a lead-free variant for ball valve applications involving potable water. Brass exhibits superior resistance to corrosion in comparison to bronze and cast iron. Brass may deteriorate when exposed to excessive concentrations of chlorine.

2) Bronze

Bronze is an alloy that consists of tin and copper, a durable and malleable material that resists rapid cracking. Bronze components are produced by casting the material into a mold or constructing a pre-cast bronze ingot. Small holes are present on the surface of bronze, which imparts a realistic, porous appearance due to the casting process. With specific additives, bronze alloys can retain a polished surface. Bronze has numerous advantages, including low cost (compared to brass), high flexibility (resistance to splitting), and corrosion resistance.

3) Stainless steel

Applications involving high temperatures and pressures are well-suited for the extremely resilient and long-lasting stainless steel. In contrast to brass, stainless steel exhibits superior resistance to corrosion and leakage. Due to its exceptional chloride resistance, ball valves constructed from stainless steel 316 are suitable for marine environments. One of the significant advantages of stainless steel, particularly in applications involving food processing, water systems.

4) WCB steel

A WCB ball valve is an industrial valve constructed from “Weldable Cast Carbon” steel of the “B” grade, known for its significant durability and robustness. The term ‘ball valve’ comes from its internal mechanism – a spherical ball with a central bore that controls the flow of substances, typically liquids or gases. When the bore is aligned with the pipeline, the valve is open, allowing passage, and when perpendicular, it’s closed, blocking flow.

18. What Is A PVC Ball Valve?

A PVC ball valve is an on/off plastic valve that contains a rotary ball with a bore. The fluid flow can be shut off by rotating the ball through a quarter turn. They are low in cost, extremely rugged, and can regulate the flow of acids, bases, water, oxygen, and corrosive materials. Although they have no mechanical strength, P.V.C. ball valves are very low-temperature- and pressure-resistant. Like any other ball valve, P.V.C. ball valves shut off the flow by rotating a ball by 90 degrees.

P.V.C. ball valves have a rotational component called a rotary ball. Depending on the design of the valve, the mechanism for rotating the ball, which is constituted by a stem at its top, can be either manual or automatic. The valve is open as long as the handle is parallel to the line; otherwise, the valve is fully closed when the handle is perpendicular to the pipe.

P.V.C. ball valves, made of fire-resistant plastic, range from -14 °C to -140 °C in temperature. P.V.C. ball valves are flexible when it comes to usage, having a lightweight body and a smaller size; they carry out most of the functions of conventional ball valves. Generally operates optimally in the 33°F to 140°F (0.5°C to 60°C) temperature range. Although P.V.C. can resist lower temperatures, its brittleness increases significantly, leading to fracture or failure. Additionally, elevated temperatures may result in deformation and softening of P.V.C., compromising the valve’s structural integrity.

While the most common is the two-way PVC valve, other bore designs can more appropriately match the performance of an application. T-port and L-port configurations are utilized in three-way bore designs, which find utility in fluid flow mixing, distribution, and diversion applications. These designs can prove highly useful in multi-fluid and multi-type flow applications.

19. Ball Valve Vs. Check Valve

When selecting a valve for your system, understanding the differences between ball valves and check valves is essential. While both are designed to manage the flow of fluids, they operate on distinct principles and serve different purposes.

1) Method to Control

When fluid streams in the desired direction, the valve is opened; conversely, backflow causes the valve to close. Weight, back pressure, a spring, or a combination of these elements all function to prevent backflow through the check mechanism. Additionally, the term “disc” is commonly employed to denote the mechanism, whereas “ball” and “poppet” are also utilized. The disc in the form of a ball comprises the closure component of the ball valve. With a quarter-turn of the actuator, the valve is unlocked. To facilitate the passage of the media through the valve, the turn ensures that the ball’s opening is in a parallel alignment with the flow. Upon closing the valve, the ball rotates vertically to obstruct the flow, obstructing the media’s passage.

2) Materials

Metallic and non-metallic materials can be utilized in the construction of check valves. Exterior coverings are frequently constructed from plastic or metal. The most commonly used material for check valves is corrosion-resistant stainless steel, although carbon steel and forged carbon steel are also employed. Body components may be constructed from any of the following materials: brass, titanium, bronze, stainless steel, chromium, P.V.C., and C.P.V.C. Additionally, ball valves incorporate a wide variety of seats and seals. The suitability of substances for specific purposes is determined by chemical compatibility, temperature, and pressure.

3) Media

The media is essential when determining the type and pace of the actuator, in addition to the material for the valve body and disc. Materials for the valve system could be extremely diverse. Ball valves exhibit exceptional performance with both gaseous and liquid media. This valve design can be applied to challenging substances such as oxygen, hydrofluoric acid, anhydrous chlorine, and hydrochloric acid. The slurry solidifies in the cavities enclosing the ball and seats, which diminishes the effectiveness of the slurry transfer. Increased operating torque may result in valve damage. Most ball valve manufacturers recommend that trace particles not exceed 3%.

20. Ball Valve Vs. Check Valve

While both ball valves and check valves are essential components in fluid control systems, as a valve manufacturer guide their applications and types differ significantly. Understanding these differences helps in making an informed decision that aligns with the specific requirements of your system.

1) Check Valve Applications

Check valves serve the purpose of preventing backflow and maintaining pressure. They are commonly utilized as a contingency measure when the system pressure exceeds the capacity of the central gap or when a pump malfunctions. Various industries require check valves, including oilfield production, chemical, petrochemical, water, steam, and petroleum refining. Ball valves have widespread applications in fire safety protection services, chlorine producers, and circulating systems aboard ships. Due to their challenging cleaning properties, these materials are contraindicated for use in bioprocessing, food and beverage, and pharmaceutical applications.

2) Types

Swing valves, lift valves, ball valves, double-disc or wafer check valves, umbrella valves, butterfly valves, cartridge/manifold valves, foot valves, poppet valves, and pivoting disk check valves are the various types of check valves. Among the various varieties of ball valves are welded valves, single body valves, three-piece body valves, split body valves, top entry valves, and reduced port valves, as well as full port valves and v-port control valves.

21. Why Choose Plumberstar?

If you’re looking for high-quality, customized solutions for your ball valve procurement needs, Plumberstar is the place to proceed. Plumberstar is an industry front-runner in delivering reliable items that meet or exceed all criteria because of its competence in managing huge orders, using high-quality materials, and implementing stringent quality control procedures. Clients in the mechanical equipment and hardware sectors find them a perfect partner due to their worldwide presence, rapid delivery, and customized service. Count on Plumberstar’s extensive experience and dedication to providing you with top-notch ball valves tailored to your specifications.