Underfloor heating is a system that heats your home through the floor and every section. Manifolds are the central unit that controls the majority of the heating process. They are a primitive source of heating homes in winter. However, the latest systems have adopted various innovations. Traditionally, the heating systems worked by using steam to warm the houses. Yet, advanced UFH systems use manifolds, pipelines, and electrical elements below the floor. This has brought remarkable innovation and a lot more convenience to the industry.

The principle on which modern underfloor heating manifolds work is straightforward. The warm surfaces release heat to the surroundings. It lowers the temperature of the physical objects. They heat the floors, heating the entire building floor-to-floor. They cut the need to install huge radiators or other room-warming equipment. These PEX heating solutions are significant in maintaining heat distribution throughout your household. This ultimate manifold solution guide will have the underfloor heating manifold explained. We will cover their work, types, and parts to help you understand the product.

1. History of Underfloor Heating

Ancient Romans first used underfloor heating, which has been used for centuries. They kept hollow spaces behind the walls and under the floors for heating. The heat from the fire was then circulated through these spaces to warm up the floor and walls. This is an ingenious method for warmth and comfort during winter. Yet, the comeback of this system was made in Europe in the early 20th century. Earlier, they were employed in commercial and industrial settings for various reasons. Later, acceptable adaptations were made, and UFH was introduced to our homes. It has revolutionised the industry with continuous adaptations for comfort and warmth.

2. Role of Manifolds in Underfloor Heating System

Manifolds are the most active component of an underfloor radiating system. They play a crucial role; without manifolds, a UFH system can never create heating spaces. Here is the most significant role of manifolds.

1) Water Distribution

The primary role of a manifold in the UFH system is to distribute hot water. The manifold circulates hot water from a boiler or heating chamber to all sections. This water adds warmth to the walls and the underfloor.

2) Returning Water

After losing its heat in radiation, the water returns to the manifold. It collects water from different sections under the floor. Then, manifolds direct this water toward the heat source, and the process continues.

3) Controlling Zones

Manifolds play a significant role in controlling many heating zones. They allow separate controls for each section, which eases the process. With this feature, you can enjoy different temperature settings in building zones.

3. Working of Manifolds in an Underfloor Heating System

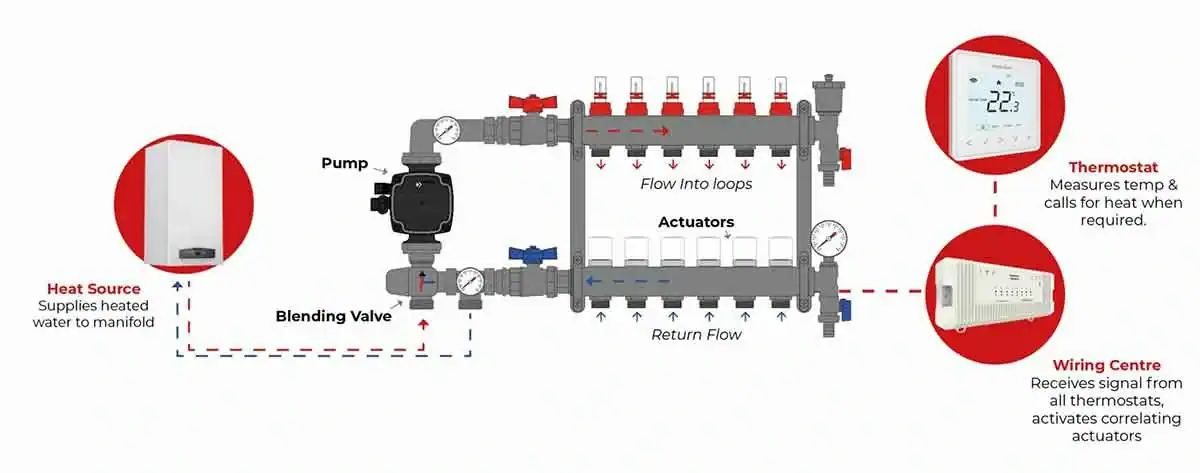

The Manifold is the pivotal component of a UFH system. They perform significant functions in heat distribution across all the sections. A manifold works by connecting the underfloor heating pipes with the heat source. The heat source can be a boiler or a heat pump, another essential system component. A mixing unit is present here, which modifies and regulates the system’s temperature. Manifolds, then circulate this warm water within all the floor circuits. This phenomenon results in an energy-efficient heating solution. The flow meter is an essential component associated with manifolds. It checks that equal water flows through different sections for heating.

The manifolds in an underfloor heating system come with valves. These valves control the flow to each circuit of the system. These valves are activated by actuators that, in turn, connect to thermostats. The thermostat detects which zone requires a certain quantity of heat. It thereby releases the corresponding message. After this forward action, manifolds also work in the flow-returning process. Water returns to the collecting chambers of the manifold. It is then sent to the heating chamber for reheating and further circulation. The process repeats as the thermostat detects a heat requirement. In this way, the working of manifolds in the underfloor heating system keeps the balance.

4. Size Division of Manifolds

The size of manifolds refers to the beam diameter. This beam transports the heating medium (often water) through the underfloor heating system. It distributes water to each section, and thus its size is significant for heating. Standard beam sizes include: 3/4″ and 1″. The most widely applicable among these is the size “1”. Larger sizes are appropriate for industries and residential buildings having high flow requirements. Thus, the size of manifolds and the beam should be considered for an efficient and robust system.

The beam size affects the following aspects of an underfloor heating system. Primarily, the beam size affects the flow of heating media. The amount of hot water flowing through a UFH system depends directly on the size of the ports or beams. The larger the beam, the more flow it will carry, fulfilling the heating needs of a large system.

For an efficient system, choosing the correct size of manifolds is necessary. If mismatched, it can lead to system disruptions and have consequences. One effect can be energy loss or poor heat distribution through different zones

5. Types of Manifolds

Types of manifolds can be sub-categorized. We may differentiate them based on their structure and material. Design variation makes manifolds suitable for different systems. While varying materials can be ideal for specific temperature-pressure conditions in an environment. Hence, both considerations should be made before selecting a final product. Here, the types of manifolds depend on structure and design.

Manifolds are versatile products often available in many design variations. Changes in structure and working mechanisms differentiate their designs. It provides maximum efficiency in a relative system. You can find a perfect manifold by comparing it with your application requirements. Here are the differences in floor heating manifold design.

1) Single-Port Manifolds

Single-port manifolds are the standard type in UFH systems. They are suitable for small-purpose applications. They have a single inlet and outlet for a relatively basic radiating system. They provide a closed-loop system for heating of space. They may have control elements like valves, flow meters, or regulators. Single-port manifolds are compact in structure and thus are appropriate for small places. It increases flexibility, so you can install them with minor changes to existing settings. The applications of these manifolds include small houses with low radiation demands.

2) Multi-Port Manifolds

As the name suggests, Multiport manifolds are hybrid types. They offer a complex system for highly demanding applications. We can connect them with multiple outlets; the inlet usually ranges from 2 to 12. Each port is connected to a zone in the building to be heated. These manifolds distribute hot water to the zones under the floor or behind walls. One can regulate temperature settings in sections using thermostatic actuators or control valves. Such devices ensure no under- or overheating in semen and maintain a balanced heat distribution. They are more common in large commercial or residential buildings.

3) Threaded manifolds

Threaded manifolds employ thread connections in an underfloor heating system. They are compatible with system expansion requirements. It is because we can add further circuits or remove existing ones due to the thread mechanism. They are user-friendly and quite easy to operate. Threaded manifolds come in various materials, though the brass one is right-sized due to its resonance with the design. This type’s maintenance requirements are very low due to the straightforward design. However, they do come with a limitation. They are less adaptable for high-pressure applications. This is because the threaded connections might not stand these conditions.

4) Automatic manifold

The automatic manifold is advanced in floor heating manifold design. PEX and water manifold manufacturers add unique components to smooth the heating process. They do not require manual controls for heating or radiating. This feature is achieved through sensors and thermostatic actuators. Sensors act when a zone has a heat deficit or receives an increased hot water supply. They immediately detect the changes and release commands to control the heat quantity. They are used in heavy-duty applications as they are difficult to maintain manually. They cut down the manual workforce and brought way more convenience by automatic means.

6. Based on Material

The material of a manifold decides the environment in which it will survive. Sturdy and robust materials are recommended for the construction of manifolds. The best among these are the brass and stainless steel.

1) Brass Manifolds

Brass is one of the favourites in plumbing equipment. Brass manifolds are widely known for their durable and corrosion-resistant properties. Brass is an excellent alloy that is ideal for handling water-related applications. Manifolds constructed from brass are best suited for high-temperature and high-pressure usage. They offer excellent conductivity and thus are perfect for underfloor heating systems. Brass is the best manifold material due to its efficiency and minor complexity.

2) Stainless Steel Manifolds

Stainless steel is a strong metal among the top-rated plumbing supply materials. Using stainless steel is a mark of strength and resistance when heating manifolds. They can handle extreme temperatures and pressure conditions, which other metals cannot. They suit both residential and household applications. Stainless steel manifolds serve for more extended periods, making them a cost-effective option. They are suitable for commercial underfloor heating systems because of their robust construction.

3) Plastic Manifolds

Plastic manifolds are another, yet least applicable type of manifold. They are appropriate only for limited usage and do not have diverse features. Hence, we can install them in small UFH systems with low pressure and temperature ratings. One reason for the low efficiency is the low performance of plastic in such environments. These manifolds are declining in usage and thus are the least considered for installation.

4) Aluminum Air Manifold

Aluminum manifolds are another considerable option that can survive pressing environments. The body is constructed mainly of aluminum and steel, giving it combined strength. It is a 4-way manifold which can undergo pressure up to 300 PSI and a temperature range of 0 to 60 degrees Celsius. It is an excellent air manifold that has a splitting option. It divides air from a single source to 4 maximum directions, and each can be cut off from the system without blocking the supply to the whole system.

7. Where Should a Manifold Be Located?

Underfloor heating manifolds are complex systems that might take up a lot of space. Although options are available with compact designs, they still need a specific space. One must pay attention to maintenance activities when selecting a manifold location. Here are some of the suitable locations for installing manifolds.

1) Floor-Mounted

Large and complex manifold systems are often floor-mounted. This is common in industrial settings and buildings where it controls heavy mechanisms. They are placed above a raised surface or a stand built to hold all the components in place.

2) Wall-Mounted

This is one of the most accessible locations for installing manifolds. They have a separate system for mounting it on the wall. A compact system is commonly installed on a wall without much trouble in small applications. It allows fair visibility of the system. In the case of manual controls, it is even more preferable to regulate and control heat distribution.

3) Invisible

The invisible location includes installing a manifold behind cabinets or some other enclosures. In this way, the system is not visible in the space setting. This hides the overall components without spoiling the aesthetic appeal of your space. This location is common in household and commercial scenarios.

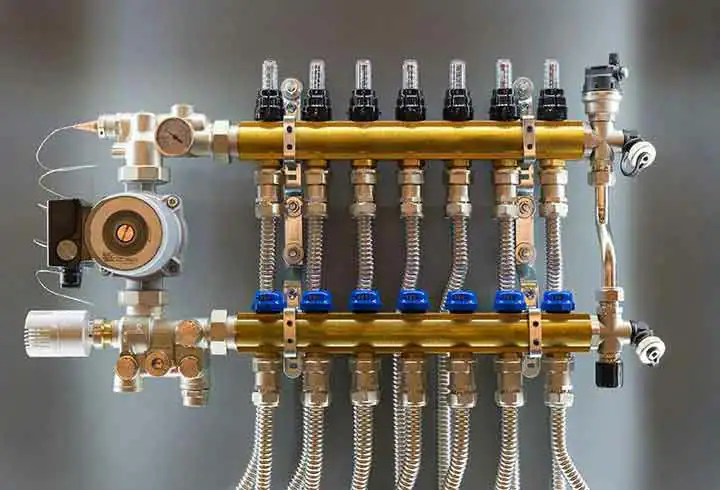

8. Manufacturing Components of Manifold

The components of a manifold are the essential parts that make up its structure. Each performs a crucial function, giving the system an overall performance. Some components control flow-related activities, while others serve the detection function. The collaboration of these parts results in constant heat in the buildings or houses. Here are the details of the components of the manifolds.

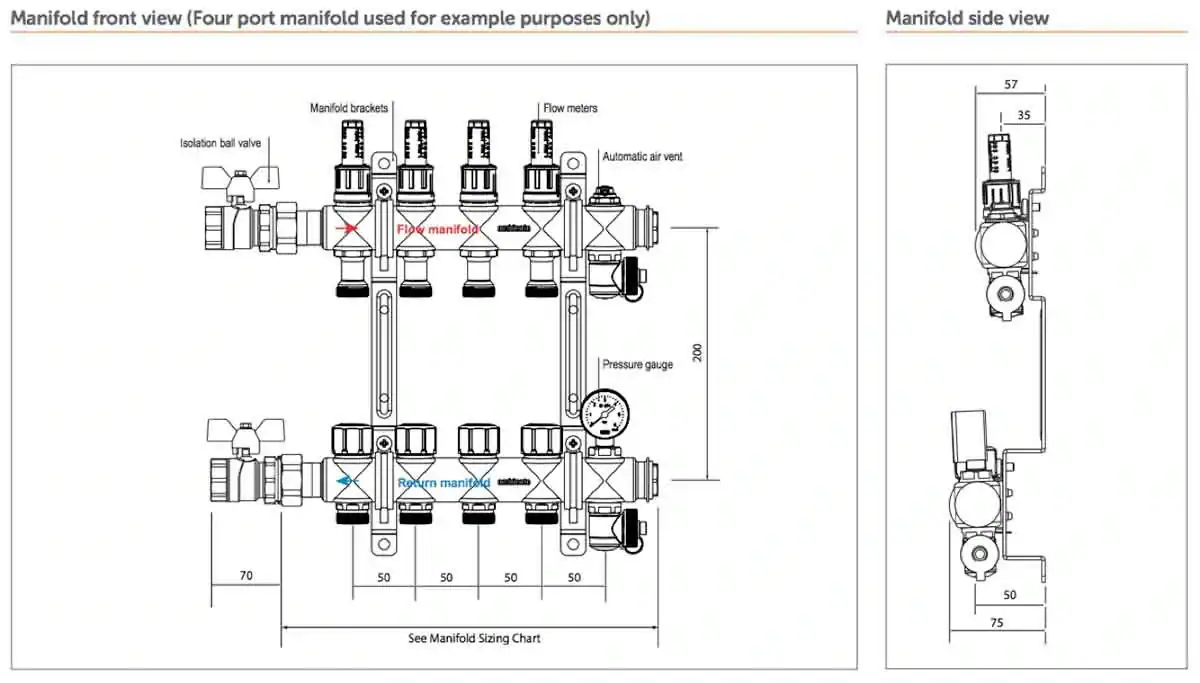

1) Inlet Ports

The inlet port is the point of entry of fluid into the manifold. This is where the function of an underfloor heating mechanism begins. This port receives hot water from a boiler or heat source, from where it circulates under the floor or behind walls. The number of inlet ports may usually vary from 2 to 12. The higher numbers are often present in complex systems.

2) Outlet Port

The outlet port is the point of fluid exit. The hot fluid leaves the manifold from here and then circulates throughout different zones. The number of outlet ports is usually similar to that of inlet ports. They are more complex and extensive than the simpler ones used in the household.

3) Balancing Valve

Balancing valves are often ball valves connected to the manifold body. These valves are central in controlling the water flow in each zone. Ball valves employ a rotating ball to move fluid or block flow. They help adjust the flow across different sections to achieve the required heating level. You might have to replace them if they are worn.

4) Flow Meter

Flow meters are monitoring devices. They measure the amount of heating fluid or hot water in each circuit. They usually keep each component working by checking on its performance. The flow meter also detects any abnormal behaviour and informs about the change. It keeps heat distribution even and balanced.

5) Thermostatic Actuators

Thermostatic actuators work in response to the thermostat’s signals about temperature changes. Whenever the temperature increases or decreases from the set limit, the thermostat detects it. It then sends signals to the thermostatic actuator. The actuator then performs accordingly by opening or closing the fluid path to attain the desired level.

6) Pressure Gauge

The pressure gauge is a device that measures the pressure within the manifold. As increased pressure could damage the manifold assembly, it checks for pressure fluctuations. It also detects potential leakages or blockages that occur due to elevated pressure. Thus, pressure gauges are safety elements within the underfloor heating systems.

7) Wiring Center

The wiring centre controls the electronic operation of the manifold in the UFH system. It connects the manifold, thermostat, and heating unit. It serves as the power control of the heating system in different rooms or apartments. It centralises the operational control for boiler and manifold distribution.

8) Air Vents

Manifolds might experience trapped air, which can build up extra pressure in the unit. It can lead to abnormality in the functioning of the system. Air vents are spaces that release trapped air from the system.

9) Pipe

The Manifold has a connected pipe body serving a central role. Its function is to transport the heating media to the heated sections safely. These pipes have robust construction to withstand high pressure and temperature. It is often made of brass or other corrosion-resistant material that can serve for extended periods.

10) Mounting Brackets

Mounting brackets are the clamps or holders that hold the manifold on the surface. This could be either a wall or a floor where you mount the manifold. Brackets keep the apparatus in place without letting it vibrate. It also ensures all components are held together so they may not cause any trouble while the manifold works.

9. Advantages of Manifold in UFH System

Manifold is a central and most active component of a UFH system. It is justified to regard it as the chief contributor to maintaining heat distribution from zone to zone. Here are the significant advantages of manifold performed in a UFH system.

1) Uniform Heat Distribution

The primary advantage of a manifold is the equal heat distribution. It is essential to balance between sections of buildings for equal temperature. It controls all the patterns and manners of heating media, giving a centralised approach. With this feature, hybrid UFH systems become more accessible to manage.

2) Customised Zone Control

The best advantage of a manifold is customising zonal control. The manifold is handled if you want a high temperature in one zone and a lower temperature in the other. The flow meters on the manifold help you set custom temperature limits. Thus, you can attain the desired heat level without worrying about keeping a check.

3) Increased Efficiency

The overall system efficiency depends on the upright performance of the manifold. It increases efficiency by reducing energy usage and ensuring even heat distribution. This relieves extra pressure and maintains consistent performance. Its prompt response to changes and fluctuations also adds to the robustness of UFH.

4) Reduced Complexity

The underfloor heating mechanism is complex and multidimensional. Manifold serves more than one function, thus reducing the need for extra apparatus. It comes with an easy-to-use interface that is easy for customers to use. Water manifold manufacturers use it to lessen the complexity and make it simple.

5) Safety and Protection

Advanced manifolds have several additional features that improve safety. They have an emergency shut-off mechanism in case of severe fluctuations. They also have pressure gauges for detecting unnecessary pressure rises. Another essential safety feature is leak detection, which saves from potential hazards.

10. Flow Meters in Heating Manifolds

A flow meter is attached to a manifold and performs a prominent function. It is a durable device that measures the flow of fluids within a pipeline or a chamber. They are widely applicable in plumbing, hydraulics, and other fields. Their precise measurement makes them a credible tool for flow measurement. Before, the underfloor heating manifold flow meters showed the reading. Then the flow rate was measured using formula calculations. Now, digital flow meters are available to give accurate readings. In Manifolds, flow meters are central to inspecting flow rates and noticing fluctuations.

Flow meter manufacturers employ safety features in these products to enhance their functioning.

1) Ultrasonic Flow Meter

These flow meters use ultrasonics to measure the flow rate. The meter releases signals in the direction of fluid flow. Some of these signals move towards the upward stream, and others towards the downward stream. The difference in time taken by both sounds gives us the velocity of the particles. The calculator in the meter automatically measures the flow rate using the velocity of particles. This type of flow meter is highly applicable in heavy-duty applications and large pipelines. Ultrasounds can travel faster and give accurate readings in such systems than any other type of meter.

2) Mechanical Flow Meter

Mechanical flow meters are the primary and easiest type of flow meter. They have the most diverse range of applications owing to their simple construction. They usually come in two designs: either shunt or propellant. The turbine inside the meter moves following one of these design structures. The fluid speed inside the pipeline rotates the turbine. The number of rotations is counted as the blades of the turbine move. Finally, the given information leads to the final volumetric flow rate. However, this type of flow meter works well under instant flow conditions. Less fluid speed may result in improper functioning.

3) Thermal Flow Meter

Thermal flow meters use heat energy to find the flow rate of fluids in a system. Here, a heated probe is placed inside the flowing liquid. An electric current is provided to keep the heat supply constant. The current indeed functions in measuring the heat loss. The higher the flow rate, the greater the loss will be. As a result, more electric current will be provided to maintain the heat supply. This is when the flow rate can be calculated. We can get the ratings by measuring the increase in current supply. Although a complex working principle, this flow meter is excellent for fluids, especially gases.

4) Magnetic Flow Meter

A magnetic flow meter is preferable for measuring the flow rate of water. In this type, the flowing media is exposed to the magnetic field. The working principle is based on Faraday’s law of electromagnetic induction. Electrodes are placed on the walls of the flow meter, which calculates the induced voltage. This voltage, along with the tube size, gives us the flow rate of media. These meters work better when the fluid moves at a relatively high speed. They are somewhat limited in their functioning and have average accuracy rates.

11. Working of Manifold Flow Meter

Manifold is a central and most active component of a UFH system. It is justified to regard it as the chief contributor to maintaining heat distribution from zone to zone. Here are the significant advantages of manifold performed in a UFH system.

Flow meters on heating manifolds are designed to meet the system’s requirements. They have a complex installation, and only a professional should install them. They calculate the flow rate in each loop in the underfloor heating system. Hot water flows through the manifold, reaching the flow meter’s transparent tube. The flow speed exerts an upward pressure on the float, which causes it to rise above. The tube has markings on it depicting specific ratings. The height of the fluid raised to the ratings shows the flow rate. Digital and automatic flow meters offer digital readings, adding more accuracy to the calculation. This feature tells manifold flow rates across different zones, as fluctuations might not be favourable.

12. Installing Manifolds in the UFH System

Manifold installation requires keen and meticulous attention. It is the critical component in any underfloor radiating system. The upright installation of the manifold leads to efficient system performance. It is often suggested to consult a professional. If you plan not to go for one, we have a solution. Here is a comprehensive manifold installation guide by Plumberstar that ensures a safe and sound process.

1) Preparing for Installation

Before carrying out the installation process, it is essential to assess the location. Understand the positions of the heating source, circuits, and other components of the UFH system. Prepare a layout for zoning of different sections of the building. Determine how many zones you will mark with their specific locations and requirements.

Once the surrounding layout is clear, move forward to the first step. Select the appropriate type of manifold for underfloor heating. Consider the number of zones and the system design for best suitability. Choose the most resilient material construction among the single-port or multi-port manifolds.

2) Mounting the Manifold

By carefully consulting the instructions of the PEX manifold manufacturer, begin the process. Finalize a location for mounting the manifold. Make sure to keep enough spacing and make proper alignments during mounting. Now, connect the heating circuits to the manifold. Each circuit connects a port to the supply manifold to distribute hot water.

At the same time, it also connects ports to the return manifold to receive water after circulation. A flow meter is installed at the distribution circuits. It will inspect the flow rates. Balancing valves should be installed on the return manifold to adjust and balance the flow among circuits.

3) Connecting Heat Source

Connect the underfloor heating system’s heat source to the supply manifold’s inlet ports. At this point, proper insulation is necessary to avoid heat loss. Connect the heat source to the outlet port of the return manifold. It will be involved in the reheating process.

Ensure tight sealing when connecting these components with the help of the right fittings. Sometimes, there is a need for circulation pumps. They ensure smooth flow through the heating system. In that case, you can connect the pump to the heat source and the manifold.

4) Installing Control Systems

The control system is responsible for maintaining a strict check on ongoing functions. Install thermostats in each zone, measuring temperature ratings in each section. Next, these thermostats are connected to manifold actuators. They will control the operation, either opening or closing, as a reaction to changes in temperature.

Smart thermostats have programmable control systems. In that case, you must integrate it with the manifold’s control system. This will be an automated thermostat that monitors temperature changes and gives remote access to the system.

5) Testing and Final Inspection

The initial testing includes checking for leaks and loose connections. Allow flow through all ports for thorough inspection. Increase the pressure to check for any potential signs of improper functioning. Adjust the balancing valve for desired flow rates and examine their performance. Sometimes, insulation may be required to prevent heat loss. Install insulation covers and finalise the actuators, thermostats, and balancing valve adjustments. Perform final inspection and check if all the components are installed and working correctly.

6) Flow Meter Monitor

Begin by locating the access point to the flow meter. Ensure all safety precautions are observed, such as wearing appropriate protective gear. Next, carefully remove any covering or protective casing around the flow meter. Examine the display panel for any signs of damage or malfunction. Check the connections and wiring for secure attachment and signs of wear. Utilize appropriate testing equipment to verify the accuracy of the flow meter readings. Finally, document any observations or discrepancies found during the inspection for further analysis.

13. Key Features to Look for in Manifolds

1) Modular Design

Modular design offers significant options for scalability. It ultimately enhances the flexibility of the system. Modular design means adding or removing components of a manifold without disturbing the assembly. It allows expansion or reduction of the existing apparatus much more quickly. It offers excellent customisation for underfloor applications and adds compatibility.

2) Material and Durability

The durability of a manifold is directly proportional to its material construction. Material and gas also impact corrosion resistance and wear-handling strength. Brass, the most common material, has corrosion resistance. Stainless steel stands for durability, and aluminium for its lightweight yet robust construction. When we choose a suitable material, it leads to a longer-than-expected system life span.

3) Compatibility and Connectivity

The manifold must be compatible with the other components of the UFH or the existing system. The connection type, threaded or compression, should match the different elements. For example, select a manifold with digital automation if the UFH system has smart controls. Consider adding thermostats and sensors to this system’s construction. This compatibility generates an overall uniformity in all functions performed by the system.

4) Flow Rate Monitoring

Monitoring flow patterns and rates can increase efficiency. Various devices can complete these desired results. Flow meters trace the rates of flowing media installed in zones of heat distribution. Pressure gauges give insight into the system’s changes in pressure. They periodically detect any pressure buildups and release commands to fix the issue. Temperature sensors ensure a zone’s heat limits do not exceed or fall below. Thus, flow monitoring features will bring much comfort to the process.

14. Finding the Best Manifold Supplier

Manifolds are continuously added to industries for their inevitable role in underfloor heating. This has increased their market value, so the manufacturers give them priority. However, a reliable product is only the trademark of a credible supplier. Finding a potential supplier seems like a hectic task due to the many options. Yet, Plumberstar has managed to list criteria that can make your finding a breeze. Below are the factors you should consider to find the best manifold supplier around you.

1) Customization

A supplier offering reasonable customisation options should be given priority. Your application might require some features that you can get added on demand. This feature is handy for large commercial orders requiring products on demand.

2) Value for Manifold

It is widely accepted that expensive products are often better at functioning. Yet, it cannot be true in every case. You have to find the best manifold supplier at a reasonable cost. They do not compromise on quality or competitive prices. Plumberstar’s range of manifolds adds value for your brand and products.

3) Delivery and Logistics

Delivery spans of suppliers can affect your project timeline. Reviewing their logistics services and capacity to handle orders is essential. They should be capable of on-time quality delivery with no damage to products.

4) After-Sale Services

While finding the best manifold supplier, pay attention to their after-sales services. This service is especially necessary for product handling, installation, and maintenance. They should offer services to resolve malfunctions promptly.

5) Supplier Reputation

The credibility of a supplier can be known from their previous dealings. A good supplier has a good history of satisfied clients, which can help you choose one faster. The market reputation of a factory is also significant among top manifold manufacturers.

6) Review Collaboration

Review the company’s collaborative approach to consignments and potential clients. Effective communication and active customer support are the keys to long-term collaboration. It makes B2B plumbing orders successful due to sufficient exchange of thoughts. Top manifold manufacturers assist you with professionals to relieve your concerns.

15. Conclusion

Plumberstar has decades of experience in manufacturing plumbing solutions. We have built hundreds of long-term collaborations with potential clients globally. We offer manifolds with a wide range of plumbing accessories and fittings. Our heating manifold range is built by the unwavering dedication of field experts. These are sustainable products with the lowest flaw ratio. Our clients offer excellent customisation options, which add to their satisfaction. Our team is always ready to assist product seekers. You are welcome to consult our technical support professionals to understand manifolds better. Explore our exclusive manifolds and book your order to join an amazing community.