Pipe fittings are the parts and components that help connect the pipelines. Different structures of pipe fittings control the flow path through different pipeline sections. They can change or reduce the flow path size and connect or split the media path in multiple directions. They are crucial for maintaining a plumbing system by providing necessary regulations. Both metallic and plastic pipe fittings are available in the market. You should choose a suitable one as it ensures a leak-proof plumbing system. The material, sizes, and dimensions of pipe fittings vary. Their selection depends on the nature of the media, pipe sizes, and pressure range of the system.

The working and installation of each pipe fitting vary. If you are looking for reliable pipe fitting manufacturers, Plumberstar has prepared a handy guide. This product solution guide will discuss different types of pipe fittings and their roles in pipeline systems.

1. Manufacturing Different Types of Pipe Fittings

Pipe fittings are significant for managing the flow regulation within a pipeline. They make media flow smooth and turbulence-free. Having the correct fittings installed ensures a reliable fluid operation. However, it is essential to learn the role of different types of pipe fittings to get excellent results.

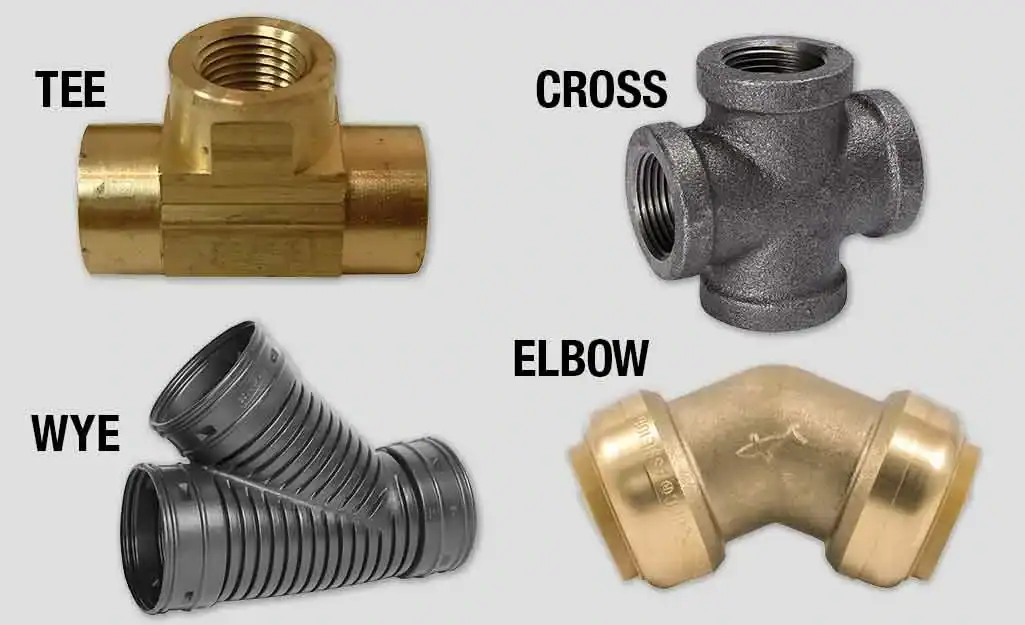

1) Elbow

Elbows are primary pipe fittings having the shape of an elbow. The purpose of an elbow fitting is to change the direction of media flow. There are usually two design variations available for them. One has an angle of 45 degrees while the other has 90 90-degree angle. These two structures are apt for similar pipe dimensions. Their connection types include sweat end or threaded.

2) Tee

A tee-type fitting has three openings with both inlets and outlets. The two outlets are perpendicular to the inlet port in a T-type structure. This design aims to merge the fluids coming from different directions. Therefore, the construction of tee-fitting should be durable. It should be able to endure the pressure produced by moving fluid. It can have threaded, male, female, or soldered connections.

3) Cross-Type

Cross pipe fittings have four ports or openings, unlike two in the elbow. Among these four, there can be three outlets with one inlet, two outlets, and two inlets, or one outlet with three inlets. These combinations depend significantly on the flow requirement at specific locations. The opening of each port is often similar in diameter, except in some cases. In reducing cross fittings, the size of the opening is relatively smaller.

4) Coupling

Copper Pipe fitting manufacturers introduced coupling fittings as an innovative approach. A coupling connects two pipes to extend the pipeline or add a new connection. The leakages in pipelines are damaging as it is not economical to change the entire pipe. A coupling is effective because we can replace the leaking part of the pipe with it. Both ports often have the same diameter, except if one side has to connect with a larger pipeline.

5) Reducer

Reducers are installed where the opening size is to be reduced. There are two popular types of reducers: concentric and eccentric. UPVC Pipe fitting manufacturers produce concentric reducers in a cone shape. They aim to reduce the diameter of the connection evenly on the same axis. In contrast, an eccentric one seeks to reduce the size parallel to the connection. Concentric applies to vertically installed pipes, while eccentric applies to horizontal ones.

6) Union

Unions are an alternative to flanges. They are applicable in small bore and low-pressure pipes where the pipe is often dismantled. They allow quick connections or disconnections in a pipeline system. The connection type of union is either socket welded or threaded ends. The components of a union typically include a female end, a male end, and a nut. Nut creates a tight seal when both the male and female ends join.

7) Adapter

Adapters are another alternative to brass pipe fittings that can extend or terminate a piping system. They are usually applicable when the sizes of the two pipes to be joined are different. In this situation, an adapter settles the odd sizes of pipes to both sizes. The best part is that they provide a secure connection to prevent leaks between the joining ends. They are usually available in various sizes and connection types to match as many pipe sizes as possible.

8) Bushings

Bushings are similar to couplings, though they join pipes of different sizes. For this purpose, they usually readjust the sizes of the female connection end. Bushings are compact and sleek fittings that take up little space. They offer the least turbulence in reducing or adjusting pipe sizes. Both threaded and non-threaded bushings exist, depending on their connection requirements. Thus, they are a convenient source of making fine adjustments without changing the entire assembly.

2. Forged Pipe Fitting Manufacturing

Pipe fitting manufacturing is a complex process. Each type differs due to changes in structure and design. However, the overall process follows a general method from initial design to final inspection. The most suitable and widely applicable method is forged pipe fitting manufacturing. Forging encompasses the structural changes in metals by applying certain temperatures and pressure. By following this process, the shape of the metal deforms, and then the desired shape is achieved. Forging is further categorized as open or closed die forging. Here is the description of the two.

1) Open-Die Forging

Open-die forging aims to deform the shape of metal sheets or raw metal. The die is the surface that contacts the metal being deformed. In open-die, these dies do not enclose the metal. Instead, they let it flow. Dies put force on the metal either as a result of hammering or stamping. The process continues until pipe fitting manufacturers get the desired shape. This type of forging results in less metallic waste. Therefore, it is ideal for the manufacturing of simple pipe fittings. The fittings can undergo multiple other finishing processes.

Some brass pipe fittings are advised to be manufactured using the open-die method. These include shafts, sleeves, disc rings, etc. The best advantage of this method is that it offers vast customization options. You can prepare a variety of variations using an open-die method due to the ease of manufacturing. The metal undergoes continuous pressure during forging, which increases its strength and endurance. This means that the product manufactured this way will have more capability for harsh conditions. Open-die forging is thus a resilient construction method allowing custom pipe fitting manufacturing.

2) Closed-Die Forging

Unlike open-die forging, closed-die forging gives an enclosed impression through dies. The dies move towards each other and, as a result, cover the whole metal under pressure. This is a sustainable process for changing metal shapes by applying a particular force. This method is suitable for small and medium component manufacturing. The heated raw material is forced to achieve a specific shape, and the metal faces a complete enclosure. This method is ideal for creating complex geometric shapes of pipe fittings. It gives fine finishing; pipe fitting manufacturers prefer this method for several reasons.

3. Raw Materials for Pipe Fittings

Raw material selection is essential for sustainable performance. As a top pipe fitting manufacturer, Plumberstar understands the demands of customers. We provide customized options for selecting pipe fittings. However, there are several raw material options for the construction of fittings. If you need to become more familiar with them, here is a guide by Plumberstar.

1) Brass Pipe Fitting

Brass pipe fittings are the most versatile of all other materials. This material is highly durable and has exceptional conductivity. It means that high temperatures usually do not interrupt the performance of brass. Brass fittings are less prone to corrosion and wear because of their natural strength. Brass fitting manufacturers find this material easy to work with because of its malleable properties. These are a favorite choice of plumbing professionals due to their dynamic properties. They can also carry chemicals, water, slurries, and flammable gases without damaging the equipment. They are available in the market in multiple shapes, sizes, and thread connections.

2) Stainless Steel Pipe Fitting

Stainless steel is a strong material for pipe fitting manufacturing. This material is non-porous, making it ideal for various applications. Stainless steel pipe fittings manufacturers use this material for its perfect strength and corrosion resistance. It has stainless steel 316, SS304, and SS201 for normal use, the materials, saving it from frequent replacements. Another benefit is their tendency to survive high-pressure and high-temperature conditions. For visible installations, they give aesthetic appeal with sleek designs. Their applications include sanitary, plumbing, food, and beverage industries.

3) Copper Pipe Fittings

Copper fittings are best known for providing efficient seals in connecting different sections. Copper is ideal for extreme temperatures and performs well in such situations. Thus, copper fitting suppliers ensure optimal construction of products to survive in harsh environments. The malleability of these products makes connections easier with multiple pipes. They are suitable for both residential and commercial plumbing.

4) PVC Pipe Fittings

PVC is the most economical option among pipe fittings’ raw materials. They are widely used due to their low cost and low maintenance requirements. PVC is the most accessible to handle, and if instructions are followed, it can work for more extensive periods. These fittings, however, do not have high temperature and pressure working ranges. Besides, PVC can even handle corrosive chemicals and such liquids. Their best applications are irrigation, residential plumbing, and drain systems.

5) UPVC Pipe Fittings

Unplasticized polyvinyl chloride is another material choice for pipe fittings. UPVC has some unique features that make it widely popular. It is resistant to oxidation, chemicals, and even sunlight. They are also suitable for underfloor plumbing installations and connections. They are also affordable as compared to metallic fittings. UPVC pipe fitting manufacturers are rapidly increasing their production due to huge demand. Their applications include both residential plumbing and commercial ones.

6) Cast Iron Pipe Fittings

Cast iron is a traditional and robust material choice for pipe fittings, known for its durability and strength. Cast iron pipe fittings are highly resistant to wear and tear, making them ideal for heavy-duty applications. They can withstand high pressure and are fire-resistant, providing safety in various installations. Cast iron is also excellent at dampening sound, which reduces noise from water flow. These fittings are commonly used in underground and exposed plumbing systems, including residential drainage, commercial plumbing, and industrial applications.

4. Selection Guide for Pipe Fittings

Selecting pipe fittings can seem a bit complex initially. However, the process becomes a breeze if you know certain factors about the product. Plumberstar helps its customers in selecting pipe fittings that best suit their requirements. Here is a guide designed specially to assist you in the selection process.

1) Fitting Function

What the fitting will do is an interesting question. You must consider this factor when choosing the correct fitting. Evaluating application requirements and finding those features in specific fittings. Decide the central job of fitty, joining, preventing, or blocking. Setting priorities narrows the options until you know the most suitable product. Another benefit is the system’s increased efficiency when it gets the suitable component instead of a false one, which may disrupt it.

2) Fitting Standards

Fitting standards are the market-set patterns that speak up for the product’s credibility. These standards are essential to consider while selecting pipe fittings, as authorities give them. These include NPT, BSPT, NPTF, BSPP, SAE, UNF, and UN. Standards vary based on location; for example, NPT is the most popular in America. The fitting standards should match the pipe standards you will install. Resonating with both standards gives a seamless working experience.

3) Operation

Determine the operation requirements of the fitting. There are usually two main factors affecting the operating mechanism. The operating pressure correlates with the pressure range at which the fitting works. It is usually measured in pounds per square inch (psi). The pressure rising or falling below this range can disrupt the fitting function.

The operating temperature range is the working temperature for a fitting. It can be calculated in Celsius and Fahrenheit; the product only functions well within these limits.

4) Material

During selection, the material of the fitting must be addressed. Two broad categories are metallic pipe fittings and plastic pipe fittings. The best practice is to choose the same material as the pipe. This ensures mutual compatibility and longevity in functioning. Transition fittings are helpful if pipelines of two different materials are to be connected. They have other materials on both ends. It makes fitting adaptable for both pipes and gives a seamless working environment. Thus, material selection must be a priority when selecting pipe fittings.

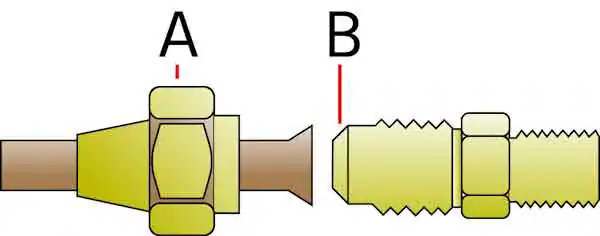

5. Flare Fittings vs. Compression Fittings

A flare fitting comprises a tapered end that joins a flared tube secured by a sleeve and a nut. It creates an excellent sealing and pressure-resistant connection. These fittings are reliable for critical and inaccessible locations. They are adaptable for wall tubing ranging from thin to medium. Compression Fittings insert one part into the tubing to create a secure connection. They are the conventional fittings that give a firm grip on the connection. Compression nuts and unions are central components that make up compression fittings. Push-fit fittings are now being replaced due to ease of installation.

In flare fittings, the flare is responsible for the sealing mechanism. Both the flare ends meet with the fitting, creating a highly resistant union to leaks.

In compression fittings, the compression ring is the primary sealing element. This ring compresses against the pipe and the seat when we apply force to tighten the nut. It leads to a sealing closure

Both flare fittings and compression fittings are suitable for relevant applications. Flare fittings are ideal for systems with a lot of turbulence and vibration. On the other hand, compression fittings are versatile and can undergo frequent disassembling. The differences between the two indicate their varying structures and functioning. However, the use of compression fittings is decreasing due to new innovative fittings.

6. Maintaining Pipe Fittings

Pipe fittings can last decades and function appropriately. But like any other plumbing component, they need maintenance. Regular checks can save you from sudden breakouts or product failure. Due to their design, some pipe fitting types require inspections and cleaning more often than others. Here are some basic instructions for maintaining pipe fittings that you can perform.

1) Inspection Tests

No matter what plumbing equipment you are dealing with, inspections are crucial. Periodic inspections will allow you to check on fitting performance. Stopping the flow, carefully check fittings. You can find potential problems quickly, but minute flaws require some tools to be checked. Check nuts, bolts, and fitting bodies for leaks or cracks. The connection between the fitting and the pipeline should be tightly held. If loose, tighten it to create a water-tight seal.

2) Upright Equipment

Brass fitting manufacturers advise on robust equipment with fittings. The bolts, nuts, or other components should suit the fitting material. You can actively check for pipeline repairs and replacements to ensure the system’s longevity. If one of the components is not functioning correctly, timely replacement is essential. The unnecessary pressure surges can affect pipe fittings and even compromise their performance. Monitor flow conditions regularly to detect any abnormality in the fitting’s functioning.

3) Cleaning and Lubricating

Cleaning increases the efficiency of fittings and renews them to some extent. Some of the fittings bear pressure fluids, often containing debris particles. They can be problematic and affect the flow path. Another problem can be increased friction at the connection points due to a lack of lubrication. Disassemble the fitting and clean it by flowing water through it. You can clean it using a piece of cloth. Then, before reassembling, apply lubricant to the joints.

4) Declogging

Clogs are the accumulated waste at the base of fittings. They may form due to waste particles in the flowing media. One of their con is that they lessen the area for flow. Second, they increase the pressure due to less surface area, which can cause cracks or bursting of the fitting. To unclog, you can remove the fitting assembly. Flush it thoroughly multiple times until the clog breaks. If the clog is still there, use an unclogging solution to break it easily. Regular cleaning is preferred to avoid future clogs.

7. Why Choose Plumberstar?

Choosing the right fittings, be mindful of pitfalls like incorrect material choice, and ensure quality checks. Consider costs beyond the product price, including shipping and extra fees. With an extensive product range and a customer-focused approach, Plumberstar remains a reliable choice in the market.