Description

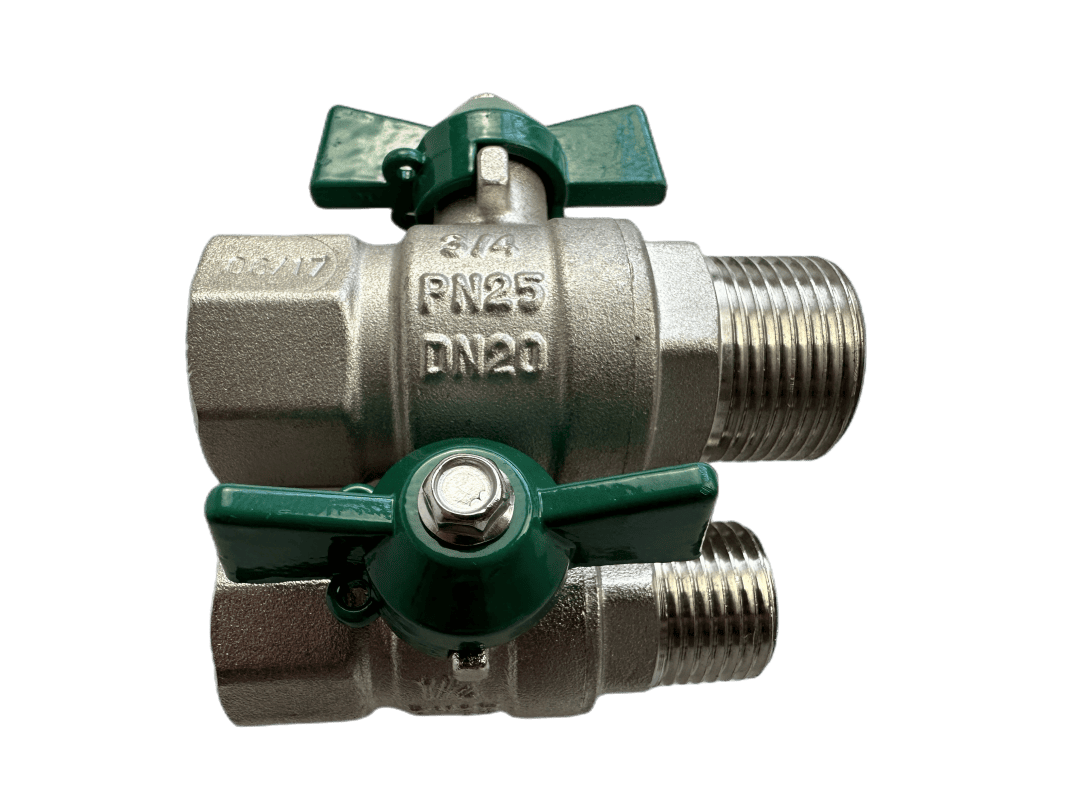

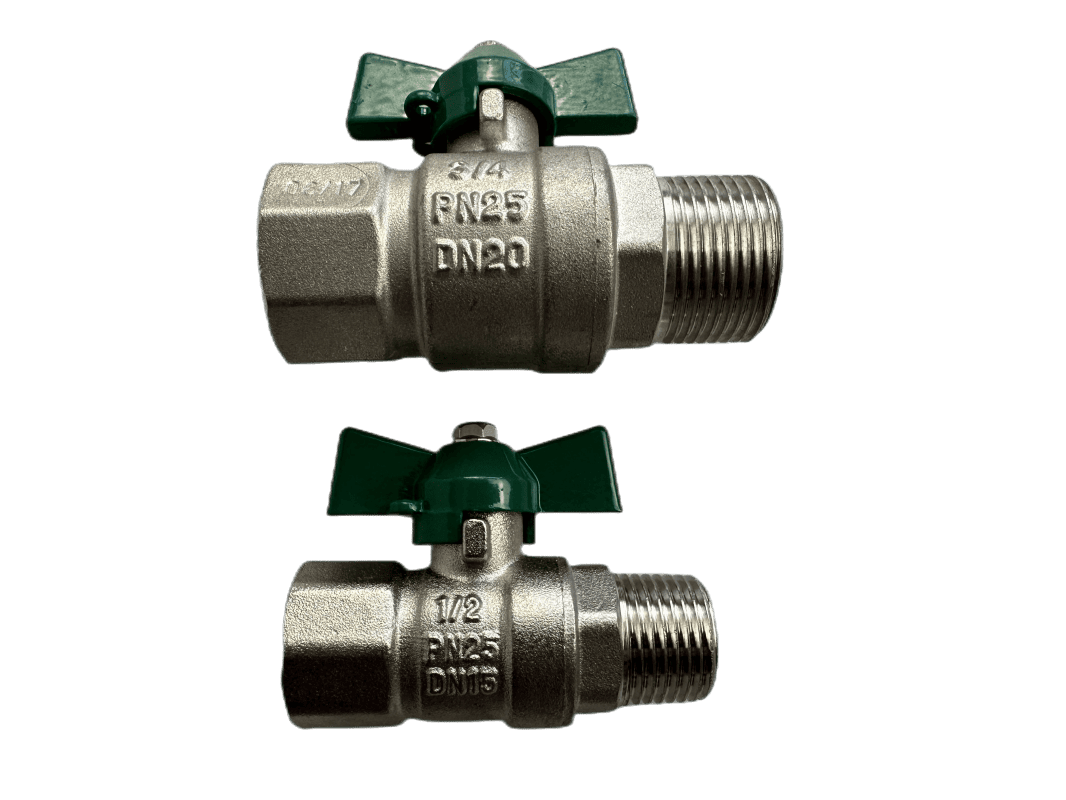

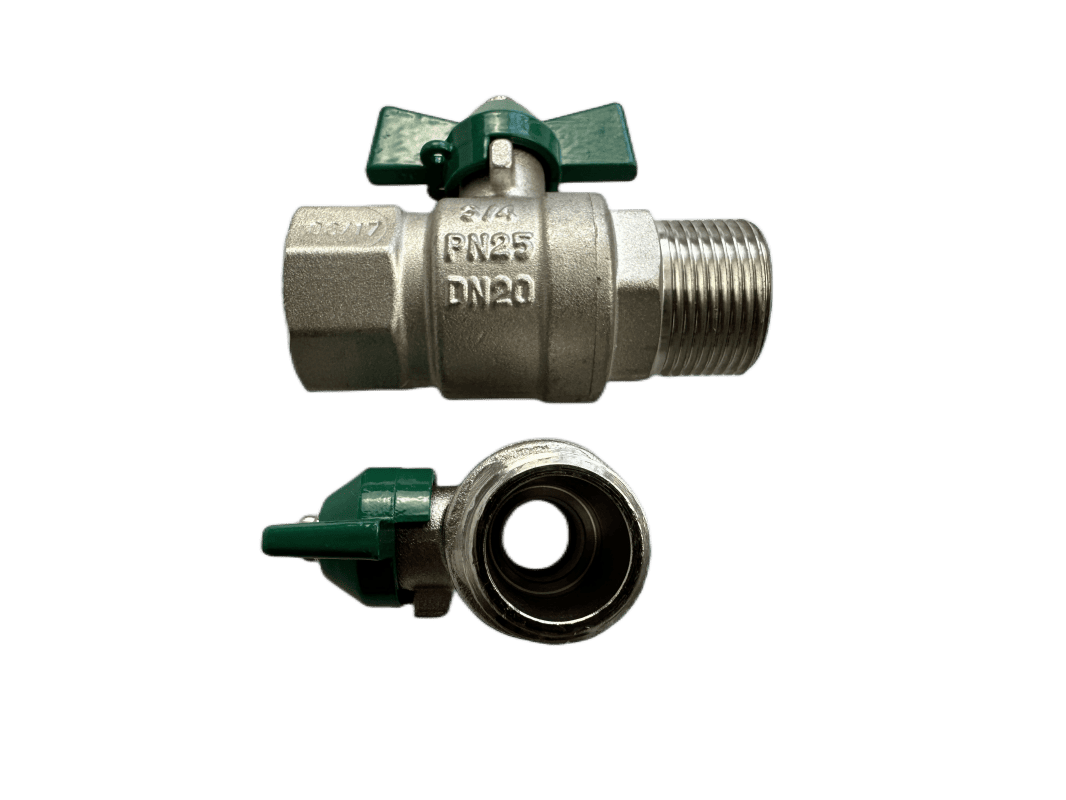

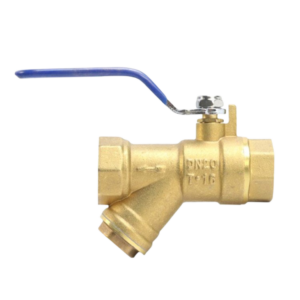

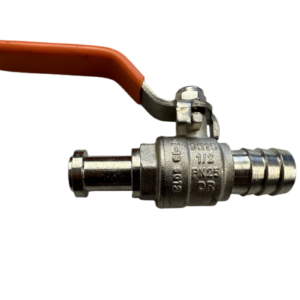

Ball valve Butterfly Handle

JX-0404

- Brass Butterfly Ball Valve

- Size 1/2″-1″

- Max work temperature; -10℃-120℃

- Max work pressure;25 bar

- Media; Water; Seawater;

- Valve bodies are made of brass for rust protection and long service life, durable and easy to use.

- Ball valves are durable, performing well after many cycles, and reliable, closing securely even after long periods of disuse.

- This thread ball valve has minimal flow resistance, and the closing piece can withstand the high-pressure difference during closing.

- The valve can realize fast opening and closing, has a compact structure, is small in size, and is lightweight.

- Ball valves can control the flow between pipes, tubes, and hoses, including water, oil, and gas.

-

- An introduction

- What is a ball valve?

- How can you know whether a ball valve is open or shut?

- Components

- Ball Valve Working

- Ball Valve Types

- Benefits of a Ball Valve

- Applications

- Final Words

An Introduction:

Ball valves are one of the valve kinds that apply in various industries. The supplies for this valve are still growing. The attention to these valves is yet emerging. Have you at any point considered how ball valves affect your applications? This blog will learn about this valve’s working, types, benefits, and much more. Further, I will show you how this valve tries to grasp well before having one for your applications.

What is a Ball Valve?

As its name proposes, it has a fantastic ball-like disc that treats as a barrier when the valve is closed. Ball valve-making teams plan the ball valve to be a quarter-turn valve. But it can be rotatory when it restrains or redirects the media change.

These can apply to applications that must tight be fixed. They are known to have low-pressure drops. Its 90 ° turn makes it simple to work whether the media has a high temperature, pressure, or volume. They are very efficient on account of their long help life.

These are good for liquids or gasses with small particles. These valves don’t function with slurries as they damage the delicate elastomeric seats. It cannot use with choking ends because grating from choking can break the seats.

How can you know whether it is open or shut?

The handle fitted in the valve will make it simple to affirm the valve status (open or close) visually.

When the valve’s handle lies to the valve, it is open, and when the handle is opposite the valve, it is closed.

The shut position 90 ° or 1/4 turn could be in either CCW or CW directing.

Components

There are many alternatives to this valve, like the three-way ball valve. The 3-way ball valve working instrument is also not the same as the standard valve. There are many ways of grouping valves. Be as it might, seven valve parts are common for all valves.

- A) Body

The body is the system of the whole ball valve—a hindrance to the strain load from the media. So there is no exchange of strain to the lines. It holds every one of the parts together. The body is associated with funneling using welded joints strung or blasted. The kind of body can group ball valves, cast, or be manufactured.

- B) Stem

The stem gives the shutting or opening of the valve. It is like what interfaces the ball disc to the switch, actuator, or handles. The stem is the one that pivots the ball base to close or open it.

- C) Ball

It is the disc—the third most significant strain limit. The tension of the media acts against the circle when it is in the shut position. Ball discs can make of steel or any sturdy material. The ball circle can either check if an appearance of the coasting valve should arise. Alternatively, it may very well be mounted like the trunnion-mounted valve.

- D) Bonnet

The cap is the covering of the valve opening. It goes about as the auxiliary obstruction for pressure. The bonnet is the thing that holds every one of the inner parts together after these can embed inside the valve body. The cap can be fashioned or projected regularly using a similar material to the valve body.

- E) Packing

It is the gasket that helps seal the cap and the stem. Many issues occur in this space, so appropriate endowment is significant. Excessively free, spillage occurs. Excessively close, the development of the stem is limited.

- F) Seat

Here and there are called the seal rings. It is the place where the ball plate rests. Contingent upon the plan of the ball plate, the seat is either appended or not to the ball.

- G) Actuator

Actuators are gadgets that make the revolution required by the valve to open the plate. , these have a force source. A few actuators can be somewhat controlled, so valves work regardless of whether these are situated in remote or difficult-to-arrive-at regions.

Actuators can come as handwheels for physically worked ball valves. Different actuators incorporate solenoid types, pneumatic types, water-powered sorts, and pinion wheels.

Working:

Generally, the ball valve working means works this way. Although of whether the actuator worked. Some power moves the switch or handles to a quarter to open the valve. This power is transferred to the stem, pushing the plate to open.

The ball plate turns, and its emptied side faces the progression of media. Now, the switch is in the opposite position, and the port resembles the passage of media. A handle stop is close to the association between the stem and hat to permit a quarter-turn.

To close the valve, the switch moves back a quarter turn—the stem moves to turn the ball plate the other way, hindering the progression of media. The control is in an equal position, and the port is opposite.

In any case, observe three sorts of ball disc development. Each of these has specific working tasks.

The coasting valve has its ball plate suspended on the stem. There is no ease at the bottom of the ball than the ball plate.

As the valve shuts. The direct upstream strain from the media pushes the ball towards a downstream seat. It provides a definite valve comfort, adding to its fixing issue. The downstream center of the valve configuration carries the whole internal tension once the valve closes.

The other sort of ball plate configuration is the trunnion-mounted ball valve. It has a bunch of trunnions at the lower part of the ball circle, making the ball plate fixed. These trunnions keep the power from the strain load once the valve closes. Thus there’s less grinding between the ball disc and also the seat. Setting pressure acts in both upstream and downstream ports.

When the valve closes, spring-stacked seats move against the ball, which pivots. These springs push the seat to the ball. The trunnion-mounted ball kinds fit applications that needn’t mess with high strain to run the ball to the downstream seat.

Major Types

Based on various styles of the body of the valve

- Top entry

- Single body

Top Entry: It is a more surprising valve plan in which the ball embeds through a hat at the highest point of the valve. The primary benefit of this is that the valve’s essential parts can s kept while the valve is yet ready to go. It uses in welded pipe frameworks.

Single body:- The ball is embedded into the body through an opening in one of the line ribs and got with a raised face gasket. It has innate strength and lessens the number of hole ways. For more types,

Benefits

Simple to use:- It is easy to introduce and work, and plastic ball valves are lightweight and simple to deal with.

Hardiness: They have a long help life and give many stretches of dependable help when utilized. These are less harmed than other valve types, and the plastic assortment isn’t destructive.

Affordability: They can buy at a lower cost than comparable items for similar work.

Productivity: It must have no grease and furnish an air pocket-tight seal with almost no force.

Application

- Chlorine manufacturing

- Oils

- Steam

- Cryogenic

- Water filtration system

- Feed and cooling water system

Final Words:

Knowing the working of these valves means you make intelligent choices about whether these valves are perfect for your requirements. If you want to learn more about the ball valves, connect with them or check the complete guide on Amazon.