Description

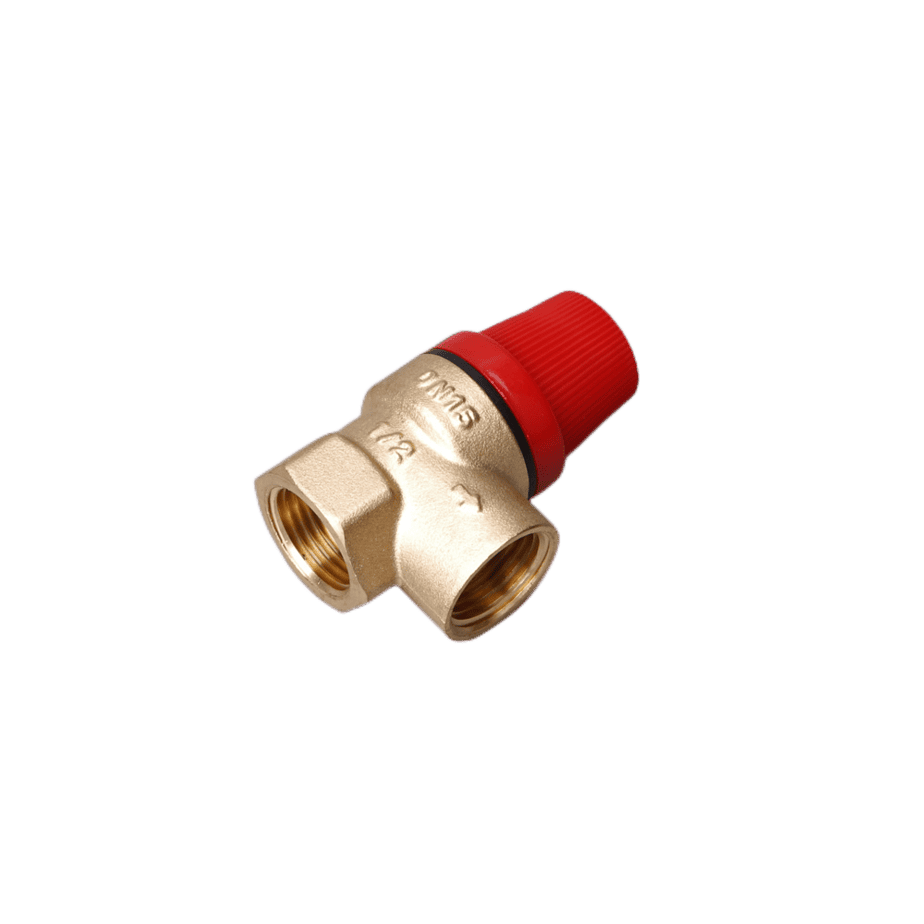

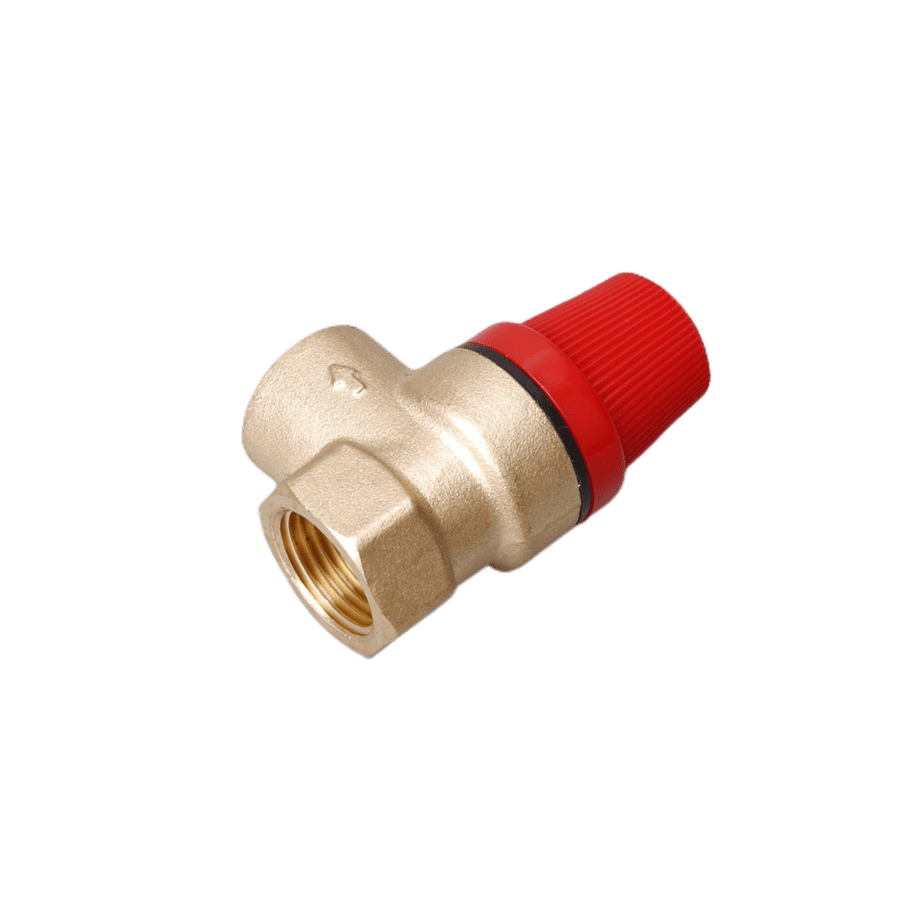

Brass Relief Safety Valve

JX-0902

- Size: 1/2 “

- Construction Material (Plumbing): Brass

- Operating Water Pressure: 1, 3, and 6 bar

- Product Type: Temperature & Pressure Relief Valve

- Temperature Range: -20°C-110 °C

- BSP/NPT connection

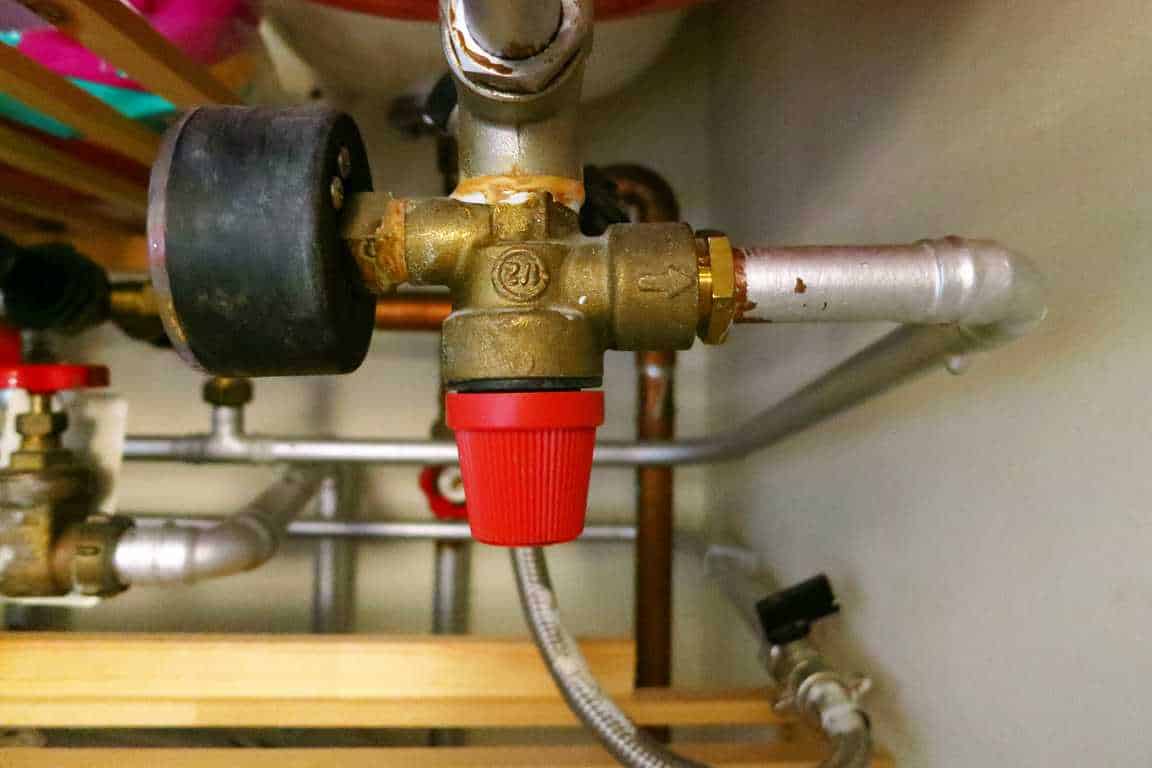

- Pressure safety relief valves are typically used to control pressure on boilers in heating systems, on stored hot water cylinders in domestic hot water systems, and generally in water systems.

- When the calibrated pressure is reached, the valve opens and, using discharge to the atmosphere, prevents the pressure of the system from reaching levels that would be dangerous for the boiler and the components in the system itself.

The brass safety relief valve is a piece of equipment found in industrial settings. The valve has two functions: release pressure and protect against over-pressure situations. These valves are designed for steam, water, gas, or other liquids that may expand when removed from the pipe. They can be found on boilers and pressure vessels such as pipelines; they will often be placed at an elevation high enough above the ground so that a rupture won’t cause any damage. These valves have many features.

Brass Safety Relief Valve with DN15 NPT female inlet and 1/2″ male outlet. This is a great safety valve for water tanks. It has a 200 PSI pressure rating, making it perfect to work with your tank!

This product is designed to work for water tanks. It has a brass body, which makes it durable and sturdy. The safety relief valve helps prevent damage caused by excessive pressure build-up in the tank during use. It is easy to install and can be used with any water tank.

The Brass Safety Relief Valve is designed for use in water tanks, as it has a 2″ female NPT connection. The valve features a solid brass body and bonnet, which can withstand high temperatures of up to 200°F (93°C). This relief valve also features a 1/2″ male NPT connection that can be used with the discharge hose.

The Brass Safety Relief Valve should be installed on the bottom or side of your water tank. You will need to drill an opening in your tank to install this safety device.

Brass Safety Relief Valve is a type of safety valve that prevents the tank from over-pressurization. The brass safety relief valve has a spring-loaded poppet that opens when the pressure in the tank rises above a predetermined value. It can be installed on water tanks, boilers, and other pressure vessels.

1) Brass Safety Relief Valve is easy to install, without flanges or welding. It can be mounted in any position and does not require the pipework to seal off the rest of the system.

The Brass Safety Relief Valve is a safety device to prevent the over-pressurization of water tanks and piping. The valve closes when the pressure reaches a certain level, preventing damage to the equipment. It also prevents flooding and allows for easy maintenance by opening when needed. This brass relief valve is designed for hot and cold water and fire sprinkler systems. Operating at a temperature range of -40 to 180 degrees F, it can be used in residential or commercial settings.

Brass Safety Valve: An Essential Guide

Safety valves are critical components in various systems, ensuring that pressure within a container or system does not exceed predetermined levels. Among the materials used for manufacturing safety valves, brass stands out for its durability, corrosion resistance, and overall reliability. This guide delves into brass safety valves, discussing their mechanics, benefits, applications, and more.

Understanding the Brass Safety Valve

A brass safety valve is a pressure-relief device primarily designed to release excess pressure from a system, thus preventing potential malfunctions or catastrophic failures.

Mechanics of Operation:

The primary function of a safety valve is straightforward: when the pressure within a system surpasses a predetermined limit, the valve opens automatically, releasing the excess pressure. Once the pressure drops to a safe level, the valve closes. This operation ensures the system remains within safe operating limits.

Why Brass?

Brass, an alloy of copper and zinc, is renowned for its corrosion resistance, making it ideal for systems with moisture or corrosive materials. Its durability and longevity make it a preferred choice for safety valves, especially in systems that demand high reliability.

Key Features and Benefits

The brass safety valve offers several advantages:

Durability:

Brass resists wear and tear, ensuring the valve remains operational over extended periods.

Corrosion Resistance:

Brass is less prone to rusting or corroding, which is essential for systems that come in contact with water or other potentially corrosive materials.

Thermal Conductivity:

Brass has good thermal conductivity, making it suitable for systems with varying temperature conditions.

Cost-Effective:

While brass might seem expensive upfront, its durability and minimal maintenance requirements make it cost-effective in the long run.

Applications of Brass Safety Valves

Brass safety valves are versatile and find usage in various domains:

Domestic Systems:

Water heaters, boilers, and other household appliances that operate under pressure often incorporate brass safety valves to prevent over-pressurization.

Industrial Applications:

Factories, especially those in the chemical, petrochemical, and pharmaceutical sectors, use brass safety valves to safeguard their intricate systems.

Transportation:

Vehicles that operate using pressurized systems, like certain trains or industrial vehicles, may utilize brass safety valves as a safety measure.

Sizes of Brass Safety Valves:

Brass safety valves are available in various sizes to cater to domestic and industrial needs. The size usually refers to the inlet and outlet diameters of the valve.

- Micro Sizes: These typically range from 1/8″ to 1/4″. They’re used in smaller applications like certain household appliances or specific precision instruments.

- Standard Sizes: The more common sizes for domestic and some industrial applications range from 1/2″ up to 2″.

- Industrial Sizes: For larger systems or industrial applications, sizes can go from 2″ up to 6″ or even larger in some specialized cases.

Specifications of Brass Safety Valves:

When choosing a brass safety valve, one should consider various specifications. These could include:

- Pressure Rating: This refers to the maximum pressure the valve is designed to handle before it opens to relieve the excess. It’s usually measured in Pounds per Square Inch (PSI) or bar.

- Temperature Rating: These valves can handle a wide temperature range since brass has good thermal conductivity. The exact range would depend on the specific alloy and design of the valve.

- Flow Coefficient (Cv): This coefficient shows how much fluid can flow through the valve once fully open. A higher Cv means more flow.

- Connection Type: This could be threaded (NPT or BSP), flanged, or a compression type, depending on the application.

- Set Pressure: This is the predetermined pressure at which the valve will start to open.

- Blowdown: The difference between the set pressure and the pressure at which the valve reseats or closes.

- Material Composition: While the primary material is brass, the exact composition, like the percentage of copper and zinc or the addition of other elements, can vary.

- Seal Materials: Depending on the application, the internal seals of the valve might be made of materials like Teflon, Viton, or EPDM, which can handle different chemicals or temperatures.

- Certifications: Depending on the region and application, the valve might need to comply with specific standards or certifications.

Understanding the size and specifications is crucial when selecting a brass safety valve. It ensures the valve functions effectively in its intended application, providing safety measures while meeting operational requirements. Proper sizing and adherence to specifications ensure the longevity and efficient performance of the valve in any given system.

Maintenance and Care

While brass safety valves are known for their robustness, regular maintenance ensures their longevity:

Regular Inspections:

It’s advisable to periodically check the valve for any signs of wear or corrosion. Even though brass resists these issues, no material is entirely immune.

Pressure Tests:

Conducting routine pressure tests ensures the valve operates at its predetermined pressure levels.

Cleaning:

Depending on the system, occasional cleaning might be necessary, especially if the system carries materials that can cause blockages.

Conclusion

Brass safety valves, with their combination of reliability, durability, and practicality, play a pivotal role in ensuring the safety of various systems. By understanding their function and importance, one can make informed decisions regarding installation and maintenance, ensuring systems remain safe and operational for years.