Description

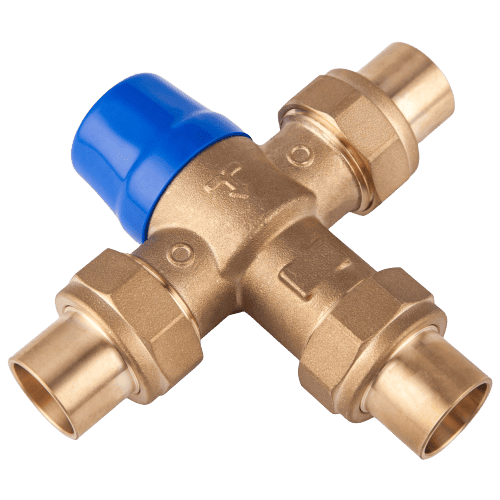

Outlet water heater temperature thermostatic 3/4-Inch lead-free brass mixing valve

JX-0322

Thermostatic Mixing Valve

Size;3/4 inch and 1inch

Work Pressure;0.03-1MPa

The cold water temperature; is 5-29℃

Hot water temperature;50-80℃

Material;brass according to customer requirements, the GeneralHPB57-3 HPB58-3 HPB59-3 DZR cw617n CW614N,Low lead

Surface Finish; brass, nickel-plated, or chrome

Can according to the need to regulate the water temperature of hot and cold water to mix, the required temperature can be quickly reached and stabilized, ensuring a constant water temperature

They are widely used in electric water heaters, solar, and central heating water systems.

Water Thermostatic Mixing Valves

Water Thermostatic Mixing Valves are an essential component of any plumbing system. They regulate the temperature of the water and help prevent Legionnaires’ Disease from occurring in a building’s water supply. This type of valve works by combining hot and cold water supplies before they reach the tap, thus ensuring that the correct temperature is always maintained.

Thermostatic mixing valves are very easy to install and can be incorporated into existing plumbing systems without much difficulty. As well as regulating temperatures in a building’s piping network, these valves act as a backflow prevention device. This means that dirty or contaminated water from one part of the system cannot ‘back flow’ into another section, potentially causing illness. The valve will also shut off if an unexpected rise or fall in temperature is detected, providing added safety for those using the system.

Benefits of TMVs

Thermostatic mixing valves (TMVs) are a critical component of modern plumbing systems, providing temperature control and water safety. TMVs provides users with several important benefits that can help improve the efficiency and comfort of any building or home.

Firstly, TMV-controlled systems allow users to maintain a constant water temperature while using multiple outlets simultaneously. This eliminates the need to manually adjust temperatures between each outlet, ensuring that each user is comfortable. Additionally, since TMVs acts as a regulator for hot and cold water supplies, they can reduce energy costs by preventing extreme temperatures from entering the system.

Furthermore, TMVs can prevent scalding or thermal shock caused by sudden changes in temperature – making them essential for homes with young children or elderly adults who may be more prone to injuries from high water temperatures.

Installation Requirements

Installing a water thermostatic mixing valve is an important decision for any home. Not only can it help maintain a constant, safe temperature for showers and bathtubs, but it can also provide added protection from bacteria and other contaminants. Before installing one of these valves, however, homeowners must first understand the installation requirements that come with the product.

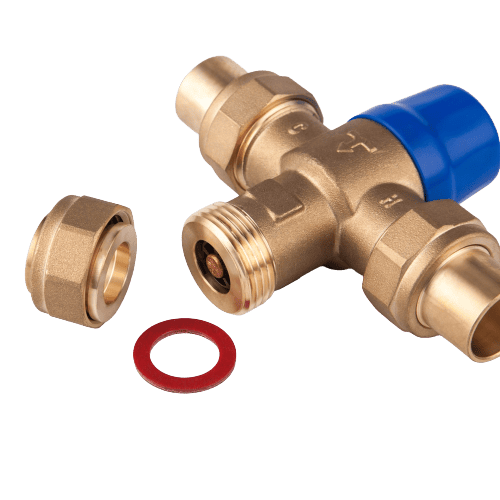

For starters, the water thermostatic mixing valve must be installed on a dedicated cold-water line before it reaches hot water heaters or boilers; this ensures that all the mixed water comes out at a regulated temperature. It is also essential to ensure that the piping leading up to the valve is properly sized; too large of pipes can lead to reduced pressure and inefficient performance. Additionally, ensure enough room has been left around the valve during installation to allow for any possible maintenance in the future if needed.

Different Types of TMVs

Thermostatic Mixing Valves (TMVs) are an important component of any plumbing system. They play a vital role in preventing scalding incidents by regulating the water temperature to safe levels and ensuring consistent temperatures throughout a building. They also minimize risks of cross-contamination, as they mix hot and cold water, so there is no need for separate outlets.

There are several different types of TMVs available on the market today, each designed to provide a unique set of features depending on the user’s specific needs. The three most popular types include manual valves, which require constant adjustment, pressure-balancing valves, which maintain constant hot and cold pressures regardless of conditions downstream; and thermostatic valves, which offer precise temperature control to ensure consistent output temperatures regardless of system demands. Each type has its advantages and should be selected carefully based on its intended application.

Maintenance and Cleaning

Maintenance and Cleaning of a Water Thermostatic Mixing Valve

Maintaining and cleaning a water thermostatic mixing valve is important to keep it functioning correctly. Regular maintenance will ensure that the valve works correctly and provides adequate protection from unwanted temperature shocks. Cleaning the valve also helps ensure that all components are operating as designed, reducing wear on the device’s internal parts. Here are some simple steps to help maintain and clean your water thermostatic mixing valves:

First, shut off the main water supply before beginning any maintenance work. Then, open each outlet simultaneously while running hot and cold water through them. If any reduced pressure or flow comes out of any outlets, replace those parts with new ones if needed.

Cost Considerations

When installing a water thermostatic mixing valve, cost considerations are an important factor. Before choosing a particular type of valve, it is essential to understand the cost breakdown and determine which model best fits within budget constraints.

The cost of a water thermostatic mixing valve will depend largely on its features and capabilities. A basic valve may be available for as little as one hundred dollars, but higher-end models can run much higher in price. Installation costs should also be considered, as well as any additional components that may need to be purchased, such as pipes or hoses. The overall size and complexity of the project can have a major impact on total costs.

It is also important to consider the potential long-term savings associated with installing a water thermostatic mixing valve.

A mixing valve is a device that controls the flow of hot and cold water in your home. The thermostatic mixing valve has an adjustable temperature dial to control the temperature at which the water will be mixed.

The outlet (hot) and return (cold) are connected to separate pipes, usually with a T-joint fitting on one end. A third pipe connects them inside the valve body, where they mix their contents before flowing out through nozzles or spouts on each side of the body. This arrangement is typical for faucets but can also be found in plumbing fixtures like showerheads and bidets.

This thermostatic mixing valve controls the water temperature in your shower or bathtub. The 3/4-inch lead-free brass construction is durable, long-lasting, and corrosion-resistant. In addition, this outlet mix valve has a temperature range of 40°F to 109°F in increments of 1°F, so you can be sure it will work for any installation. This product also meets all current codes and standards, including ASSE 1061, ANSI A112.18.1M -2015, and ISO 9920:2010(E) Standards (CSA B125).

A mixing valve is a device that connects to the hot and cold water pipes in your home. It allows you to control which water temperature flows through each tap or showerhead. The Watts’s outlet thermostatic 3/4-inch lead-free brass mixing valve is designed for gas, oil, electric, and solar heating systems. This product has been professionally tested for durability and quality assurance against corrosion. If your existing valve doesn’t meet these standards, this may be the replacement you need!