Description

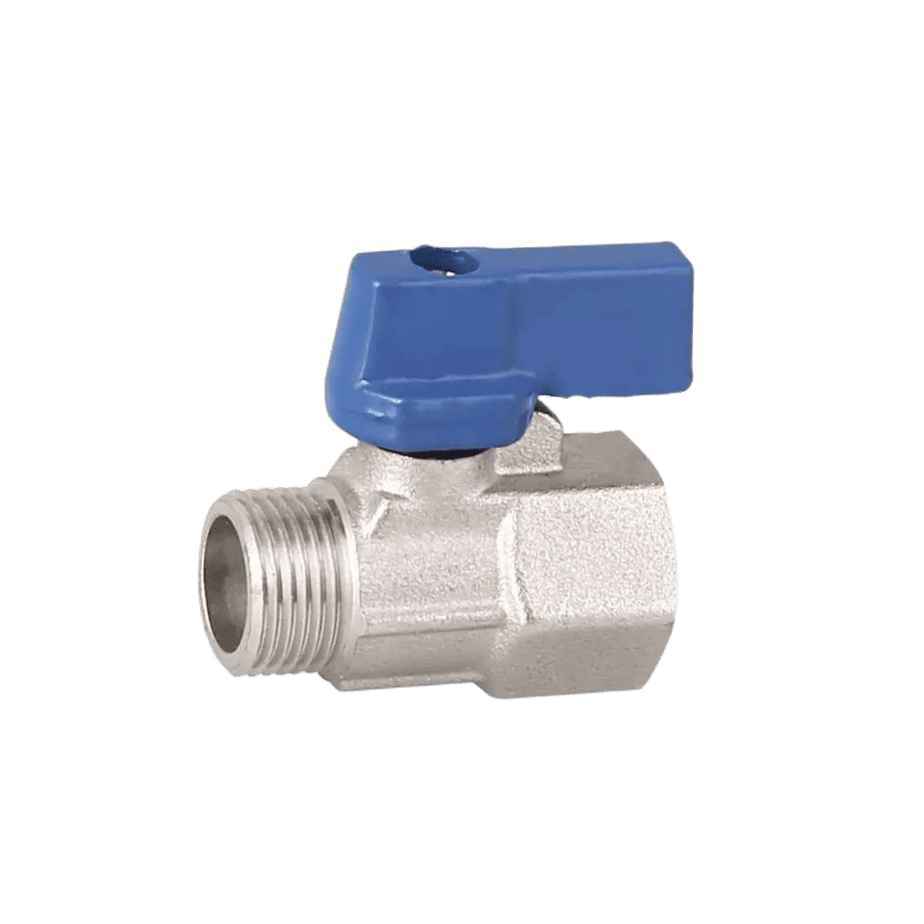

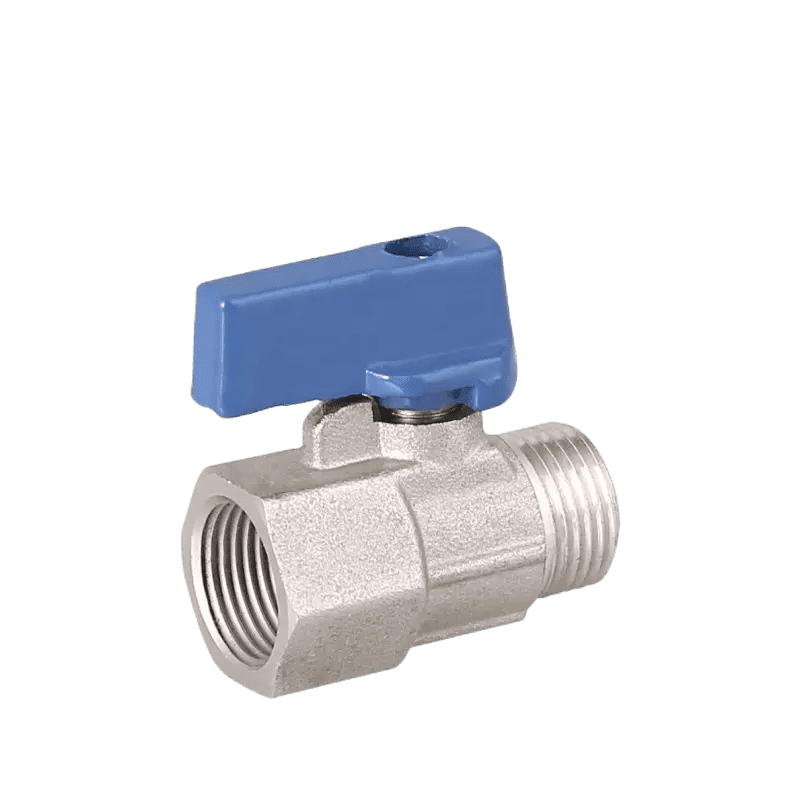

Mini Ball Valve 1/2″

JX-0415

Brass raw materials with 1/2″ inch

1/4″,3/8″,1/2″ are available

- Brass Mini Ball Valve

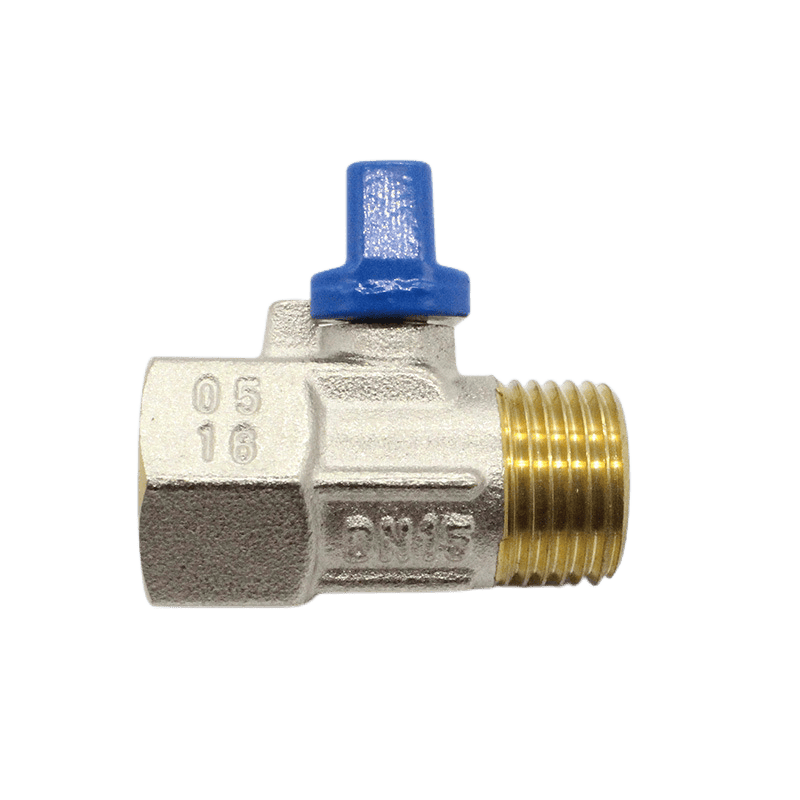

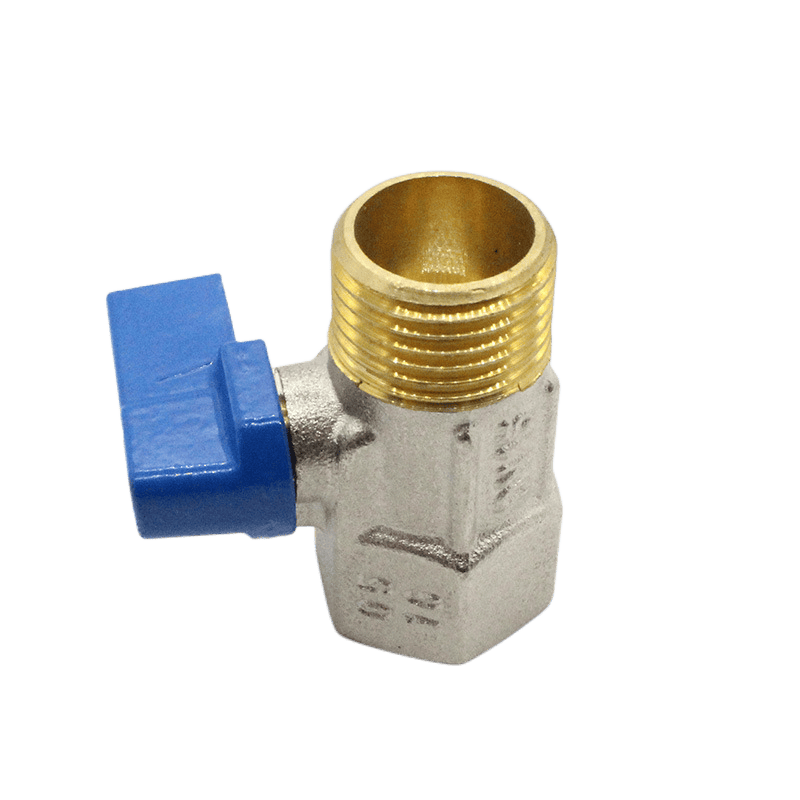

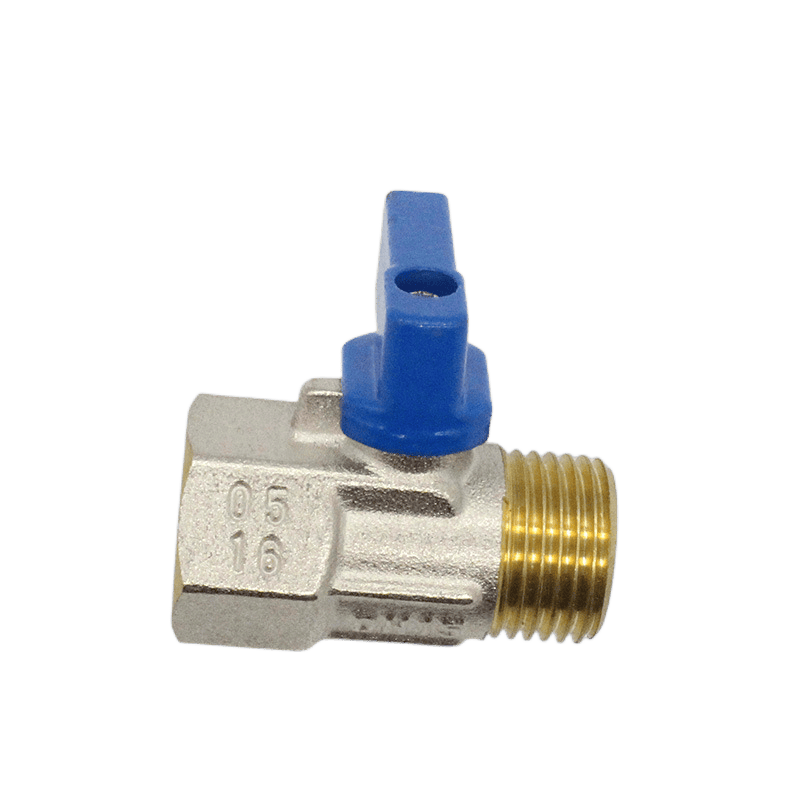

- Nickel-plated brass body – for extra strength and corrosion resistance, the working pressure of 200 psi.

- Solid chrome-plated brass ball, Female x Male NPT

- Double – seal system allows the flow to go in either direction, and heavy-duty Zinc Alloy handles

- Working temperature of 2°F to 175°F, Fast 1/4 turn open or closed operation

- Heavy Duty for Water, Oil, and Gas, each valve individually tested for maximum safety

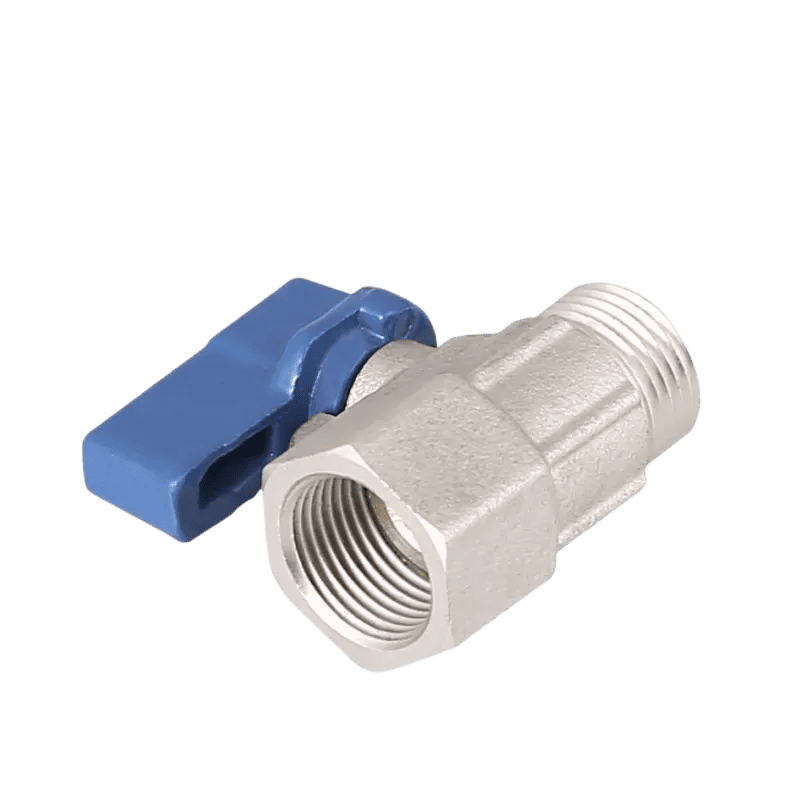

The mini ball valve is a quarter-turn type ball valve used for shut-off application in the pipework. The handle can be rotated at 90 degrees to open or close the valve. It is a threaded end ball valve where one male thread and another female side thread.

Mini-ball valves are ideal for use in small, confined spaces, where larger valves are unnecessary. They are suitable for residential and light commercial applications in domestic hot and cold water systems, natural or bottled gas, and compressed air systems.

Working pressure and temperature:

Many parameters influence the functioning pressure and temperature of a small ball valve. The first is the material used to construct the device. In theory, some materials are stronger than others. We are allowing them to resist higher working pressures and temperatures. Due to their inherent properties, other materials may be intolerant to high pressure and temperature. The little ball valve’s size is also a deciding factor. They are available in various diameters. It is vital when selecting the best temperature and working pressure. Larger diameter ball valves can ensure higher working pressure and temperature.

Also, the type of material that passes through the device is essential in determining these features. A few variables influence a mini ball valve’s working pressure and temperature. Most accessible mini-ball valves have an average working pressure of 250-1000 psi.

Most mini-ball valves have a temperature range of -30° F to 325° F.

Limitations

Mini-ball valves are a great way to control the flow of fluids in piping systems. They can be used for low-pressure applications or even high-pressure uses such as water and gas supply lines. However, some limitations when using mini-ball valves should be considered before making a purchase.

One limitation of mini-ball valves is their size; they are made to fit tight spaces but may not work with larger pipes or higher pressures. The valve must also be specifically designed for the type of fluid being handled; different materials will require specialized mini-ball valves. Additionally, spring-loaded versions offer more precise control but may not be suitable for extreme temperatures and pressures due to their design.

Finally, users must take care when installing mini-ball valves since improper installation can cause leakages and other issues that could lead to costly repairs.

Installation Considerations

When installing a mini ball valve, there are several key considerations to keep in mind. First and foremost is size. Mini ball valves are available in various diameters and lengths, so it’s important to ensure that your valve will fit into the available space. Additionally, pay attention to the type of material the valve is made from; some materials may be more suited for certain applications than others.

The pressure rating of your mini ball valve is also important when deciding on installation. These valves can support pressures up to 1,000 psi or higher depending on their construction, so make sure you choose one that meets your specific system requirements. Finally, consider any special features necessary for your application – such as extra ports or automated controls – before making a purchase.

Definition: What is a Mini Ball Valve?

A mini-ball valve regulates and controls the flow of liquids or gases in industrial settings. It works by using a small, hollowed-out ball with a hole in the center that fits snugly into the opening of a larger pipe. The ball can be turned on its axis to open or close off the flow of material through it. This makes it an efficient and cost-effective way to adjust fluid pressure, control temperature, and maintain quality control in manufacturing processes.

Mini-ball valves are advantageous because they’re typically much smaller than standard valves, making them ideal for tight spaces where installation would otherwise be challenging. They also require very little maintenance due to their simple design and durable construction, meaning they can last for many years without needing repair or replacement.

Types: Different Variations of Mini Ball Valves

Mini-ball valves are a type of valve used in many different applications. They offer a reliable and efficient way to control the flow of liquids or gases within an industrial environment. As such, they come in various sizes and variations to meet the needs of different industries. There are two main types of mini ball valves, namely threaded and flanged.

Threaded mini-ball valves have an internal threading that allows them to be secured directly into a pipe system without additional components. These mini-ball valves are ideal for low-pressure applications, as the internal threads provide superior sealing properties compared to other methods. On the other hand, flanged mini-ball valves require additional components such as gaskets or O-rings to ensure secure connections between pipes and vessels.

Installation: Installing Mini Ball Valves

Mini ball valves are plumbing fixtures that provide convenient control of water flow in both residential and commercial settings. The installation process is easy and efficient, allowing even the most inexperienced do-it-yourselfer to complete the job in no time. Here, we will explore how to install a mini ball valve correctly, ensuring that it offers years of reliable service.

First, turn off the main water supply and drain any remaining water from the existing plumbing. This can be accomplished by turning on a faucet connected to pipes with the valve or opening an outside spigot until no more water flows out. Once this is done, disconnect all existing lines from where you plan to install the mini ball valve. Measure twice before cutting so you don’t have too much or too little pipe left exposed.

Maintenance: Caring for Mini Ball Valves

Mini ball valves are great for plumbing applications as they provide reliable and easy operation. A mini ball valve is a small valve used to control the flow of liquids or gases in tight spaces, such as those found in water treatment systems, industrial process lines, or medical equipment. To ensure that your mini ball valve functions properly and lasts longer, it is important to practice effective maintenance techniques.

Regularly check the valve for any debris or corrosion that might affect its performance. Clean the valve’s exterior with soap and water using soft cloths or sponges to prevent damage from scrubbing it too hard. Inspecting internal parts can be done through visual checks or by taking apart specific components if necessary.